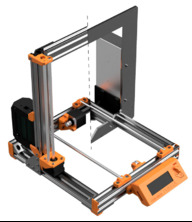

Prusa i3 Bear Upgrade V2

Discussion in '3D printers' started by pek, Feb 8, 2018.

Prusa i3 Bear Upgrade V2

Discussion in '3D printers' started by pek, Feb 8, 2018.

Stronger frame for Prusa i3 MK2(s), MK2.5 and MK3 3D printer

Page 6 of 8

Page 6 of 8