C-Beam Prefab Untitled

Discussion in 'CNC Mills/Routers' started by ahayden, Sep 24, 2016.

C-Beam Prefab Untitled

Discussion in 'CNC Mills/Routers' started by ahayden, Sep 24, 2016.

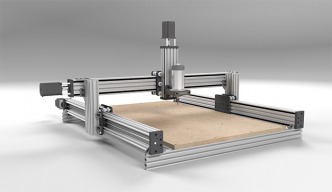

The C-Beam Prefab Untitled is designed as the cartesian compliment to the C-Beam XL. With the exception of requiring a couple more 1000mm C-Beams and lead screws, the build requires a minimum of additional parts. The primary intention of the build is to maximize the cutting envelope while still staying within the sweet spot for C-beam rigidity. This design can easily be modified and allows for further custom structural components to be cut with the initial build platform.

Page 1 of 2

Page 1 of 2