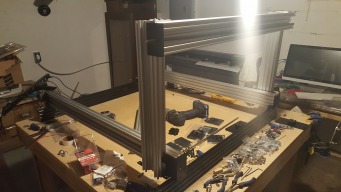

I started with an OX XL but the belt drive had too much play for any real cnc work and belts were stretching. There was also too much movement laterally in the Z axis even with the wheels pretty tight. I decided to go all screw drive with as many c beams I could put into the build. Instead of gantry plates I went with 2 500MM Cbeams mounted to the bottom XL plates with 4 of the solid corner blocks.

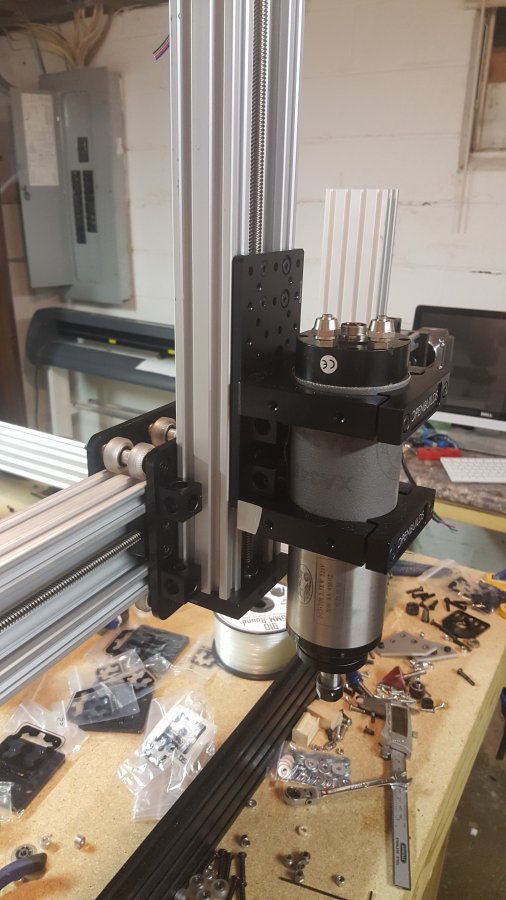

The reason I went 500MM high on the Z is to give more clearance with the larger spindle allowing for longer 1/8 bits and taller work pieces.

Build of all cbeams and screws.

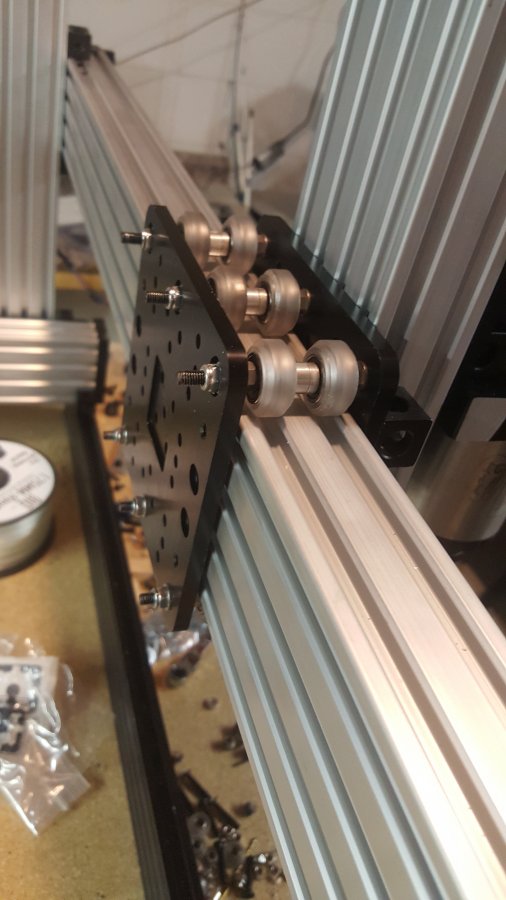

Y is 2x 1000MM cbeam with 8 wheels and XL plate

X is 1000MM cbeam with 8 wheels and XL plate

Z is 500MM cbeam with 8 wheels and XL plate

Nema 23 motors

1.5K spindle 65MM ER 11

As I get the rest of the parts in im waiting on Ill post more pics.

My electronics box I made:

12/8/2016 - Update on where its at. So i have it all together and its rock solid using the 8 wheel kit however there is enough deflection on the X cbeam along the Y axis you could use it as a swing. It appears to be give in the wheels sitting in the track. With less than 6 lbs of pressure front to back I can deflect it 3 inches in both directions. I have ordered 2 XL plates and going to try to make an over the top gantry with more wheels to see if I can offset this some. Realistically Id like to have to solid rails for the X but ive spent a fortune so far in Cbeam parts I am going to keep going and see where it takes me. Side note if anyone needs the small Cbeam plates I have like a dozen or so still in the wrappers and I have the plates from the original OX build if anyone needs them or would like to do some part trading.

12/15/2016 - Update. I got more parts in today the XL plates are much better. There is almost 0 deflection now. Testing with 50lbs of pressure front to back im getting 2mm of movement which should be extreme in comparison to pressure on the spindle moving through materials.

Pure Cbeam 900x1000

Build in 'Cartesian Style CNC' published by James Hayes, Dec 15, 2016.

This is a pure cbeam build to maximize envelope and rigidity. All the parts used are available from open builds.

-

-

-

- Build Progress:

-

- Build in Progress...

mikework, Bernie CLark, silopolis and 3 others like this. -

-

Build Author James Hayes, Find all builds by James Hayes

-

- Loading...

-

Build Details

- Build License:

-

- CERN (CERN-OHL1.2+) Open Hardware Licence

Reason for this Build

I needed a more rigid machine that could not only hold the weight of a larger 1.5K spindle and mount but also withstand the forces of higher feed rates.