Build List

-

Active Filters:

2

Build Author

pedrofernandez

Views

8590

Build Author

pedrofernandez

Views

8590

K40 Cube Laser Cutter

The k40 cube is a laser cutter build using mostly stock parts of the chinese k40 laser

Build Author

Rob Mahan

Views

11433

Build Author

Rob Mahan

Views

11433

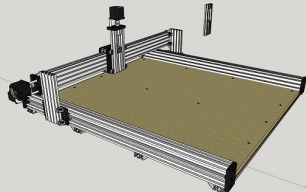

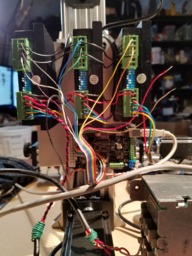

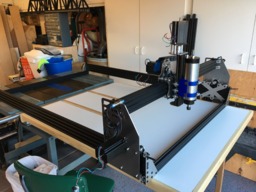

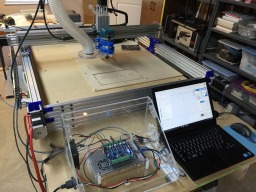

Rob's C-Beam Machine XLarge

This is my first CNC router build, so I started with the OpenBuilds C-Beam Machine XLarge mechanical bundle, including four high torque stepper motors. I took my time with the mechanical build, sought and found some great help for my control system, and designed and built a custom cabinet to house everything.

Build Author

Rick Holder

Views

13694

Build Author

Rick Holder

Views

13694

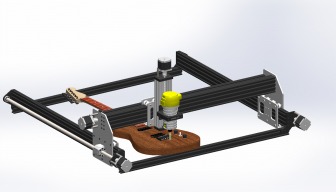

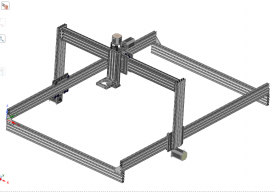

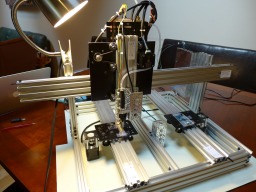

Gantry Type CNC with Makita Router

The machine has met and exceeded my expectations on repeatability and accuracy. Cost was approx £600 including the Windows tablet.

Build Author

SCYBUCK

Views

4265

Build Author

SCYBUCK

Views

4265

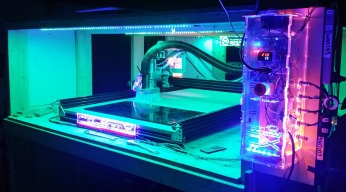

KYO SPHINX a la' SCYBUCK

KYO SPHINX, CENTROID ACORN, GECKO 540, HALL EFFECT LIMIT SWITCHES, 2.2 KW, 24,000 RPM SPINDLE, WATER COOLED, 600 oz-in STEPPERS, INTENDED TO CUT ALUMINUM.

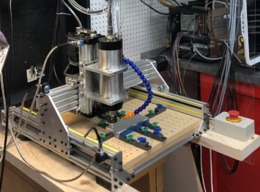

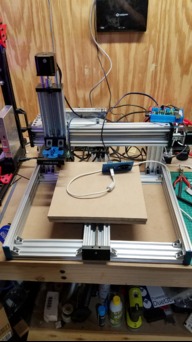

Desktop CNC

This unit is made with openbuild v-rail and c-beam. using direct drive with lead screws. Nema23 motors

Build Author

Carl Siren

Views

6187

Build Author

Carl Siren

Views

6187

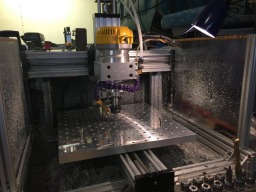

CNC-machine 650by700

A home-made CNC-machine with a 1.5 kW air cooled spindle motor suitable for milling materials such as wood, plastic and soft metals. The work table is 650 mm wide by 700 mm deep and the maximum movement is set to 560 mm for the x-axis, 480 mm for the y-axis and 105 mm for the z-axis.

Build Author

Julius

Views

23526

Build Author

Julius

Views

23526

OX Balls - 1605 Ballscrew Powered 1000mmx1000mmm OX derivative

1000x1000mm Ballscrew driven OX Derivative. Dewalt 611 spindle and TB6600 Drivers.

Build Author

Sprags

Views

1776

Build Author

Sprags

Views

1776

C-Beam Kyo Sphinx 10060

More stuff here.

Build Author

Beam

Views

9194

Build Author

Beam

Views

9194

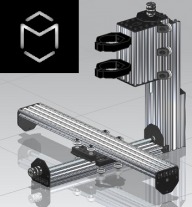

DIY Flywheel Camera Slider

My take on a non affordable slider.

Build Author

TurfnSurf

Views

4937

Build Author

TurfnSurf

Views

4937

3-Axis Plywood CNC

Theoretical Working area: 38" x 24" x 6" Actual Working Area: 31" x 23.6" x 4" Positioning Accuracy: about 0.01mm

Build Author

Axnfell

Views

2157

Build Author

Axnfell

Views

2157

WorkBee 1000x2000 ACME Screw Version

Hoping to build a WorkBee 1000 x 1000 (2000) from parts and not a kit, cannot afford the kit in full so going the long way round...

Build Author

pedrofernandez

Views

6556

Build Author

pedrofernandez

Views

6556

ACRO 20x20

The Acro Laser Machine Build

Build Author

obmilllivebuild

Views

4642

Build Author

obmilllivebuild

Views

4642

Live C-Beam Build @ MRRF2018

Contained within are links to our OpenBuilds sponsored C-beam Machine live build taking place at MRRF 2018 (Midwest Reprap Festival) on March 24 and 25, 2018. There will also be some build images and a few 3D printed STL items that were added.

Build Author

Gooshpoo

Views

7847

Build Author

Gooshpoo

Views

7847

Gooshpoo's H style cnc machine

A cool project about my cnc machines unique style.

Build Author

ymilord

Views

21371

Build Author

ymilord

Views

21371

C-Beam Rigid - 'The Hog'

C-Beam Machine baseline build. DW618 Spindle. SuperPID. Gcode Controlled Mist Coolant. Rigid Work Surface. NEMA 23 (425oz-in) Leadshine 4 Axis Stepper Driver. LinuxCNC (MachineKit) Tool Touch Off Probe.

Bedroom Builds (BrB) DIY CNC

So I am employed in the automotive industry and I walk by thousands of dollars of CNC products daily that are no use to me due to being a Technologist and not a machinist. So therefore with some research I found openbuilds and their great selection of products to build my own CNC. This CNC will consist of 4 axis one removable 360 degree axis for turning alongside a x axis table Y axis stationary gantry and a Z axis attracted to the Y axis linear actuator.

Build Author

Rob Withoff

Views

3757

Build Author

Rob Withoff

Views

3757

Mini-Mill Enhanced

Some enhancements of the basic mini-mill

Build Author

Daniel.korneliussen

Views

2550

Build Author

Daniel.korneliussen

Views

2550

Reprap prusa mendel i2 Frankenstein 2018 build

Mad plumbers choice what Else can i say?

Build Author

pek

Views

24279

Build Author

pek

Views

24279

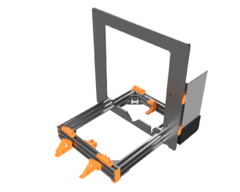

Prusa i3 Bear Half Upgrade v1.0

Stronger frame for Prusa i3 MK2 / MK2s / MK2.5 3D printer

Build Author

dmasters

Views

7225

Build Author

dmasters

Views

7225

DM C-Beam XXL Tank

1000mm x 1000mm C-Beam XXL CNC with external drivers and high torque Nema 23 motors, 2.2KW Spindle with VFD.

Build Author

Dave Pyatt

Views

3587

Build Author

Dave Pyatt

Views

3587

DaveP's Homemade CNC Project

Somewhere along the line sometime around February 2017 I got the bug in my head that I needed to build a CNC router. This is where I am today...

New 2 watt laser platform

Acro based 2 watt laser platform

Build Author

Ronald van Arkel

Views

15181

Build Author

Ronald van Arkel

Views

15181

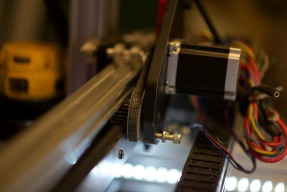

Upgrading the C-Beam machine

So we have new plates, stronger motors, belt drive reduction, but what should we do with them? In this article you might find the answer you were looking for as we took an “old” C-Beam machine and started to upgrade the X/Z body and added more torque and precision to the Z-axis.

Build Author

JWhitten

Views

12831

Build Author

JWhitten

Views

12831

Build #2 - Bigger & Stronger

Large format CNC router with a 1500mm x 3000mm cutting envelope (5 x 10 ft) strong enough to cut wood and aluminum constructed from 20-series and 40-series aluminum extrusions. Complete Project Log w/ Pictures: https://goo.gl/photos/Co81AvGwVijE2zow9

Build Author

Jens Grabner

Views

3420

Build Author

Jens Grabner

Views

3420

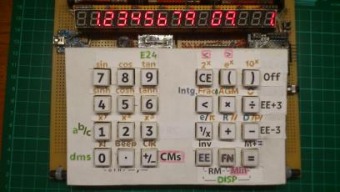

snc98_Slash-Number-Calculator

This calculator work inside with a spezail count format - Fraction as Mantisse + Dezimal exponent .. in summ 9 Byte.

Build Author

Tucstrlly

Views

7508

Build Author

Tucstrlly

Views

7508

Stainless OX Kit Build "Diamondback CNC"

A copy of the Stainless Ox by Martin Barfoed. Similar design, construction and control.

Build Author

ZacharyB

Views

4460

Build Author

ZacharyB

Views

4460

Arizona OpenBuilds MiniMill CNC

I ordered the OpenBuilds MiniMill from the OpenBuilds Parts Store http://openbuildspartstore.com/ They were out of Motors and Electronics when I ordered so I had to source these items elsewhere. But it turned out well doing it this way.

80watt Lasercutter, workingarea 105x52[cm], steel frame

I will write a short buildlog here with mostly pictures. I designed this lasercutter in solidworks(not totally finished) for a good overview and such that the steel tubes could be lasercut by a company, the metal frame is based on the lasercutter the KÄSER, which you can find on cnczone.nl. The mechical parts are designed by myself because I had no mill to my use, so the mechnical parts are lasercut(same company as tube) steelplates welded together.

Build Author

ymilord

Views

17323

Build Author

ymilord

Views

17323

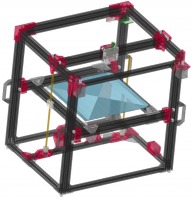

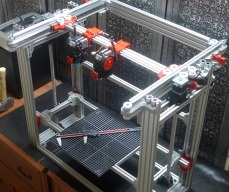

Small Portable PCB CNC Machine (CoreXY)

This is a small CNC mill/router specifically for manufacture PCBs. This is based on the corexy gantry setup. The plan is to have a small, light self-contained machine that can be used and easily but away when it's job is done.

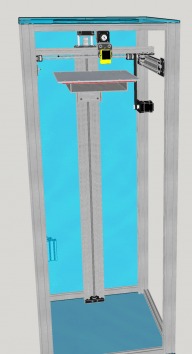

Vertical Mill

This will be a CNC milling machine. My goal is to make this mill for the minimum cost I can while not sacrificing quality. In hope of staring an educational YouTube channel on CNC milling and 3D Printing. Along with when to use both.

Build Author

ymilord

Views

11162

Build Author

ymilord

Views

11162

Kyoujin Mk1 (C-Beam /w Rack & Pinion)

C-Beam based CNC with Rack & Pinion (for the X Axis) and lead screws (for the Y Axis)

The Budget Build

An affordable large CNC machine, that so far has been easy to assemble

OXilla - a 3ft x 3ft CNC Router/Mill - Goals are strength, power and speed

This will be an ongoing log as I build this machine. Name change by popular demand - at least a couple of us. :)

Build Author

PaulS

Views

19383

Build Author

PaulS

Views

19383

UltiFaker 2 Go

This is a breakdown of how I designed the UltiFaker 2 Go as well as how I machined and assembled it. I'll include a complete BOM and all of the drawings and prices.

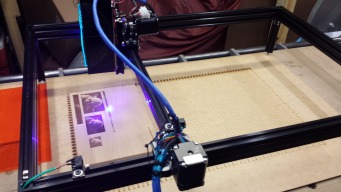

4' by 2' Lasercutter

4foot by 2 foot, 10W El-Cheapo blue laser

Build Author

Martin Bogomolni

Views

10678

Build Author

Martin Bogomolni

Views

10678

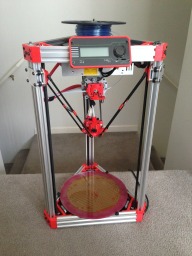

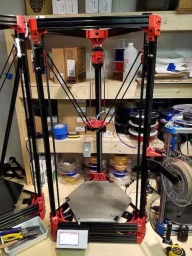

Delta-Six ( Jerry426 variant )

Building a Delta-6 variant, using recycled parts from a WolfStock Delta printer.

Build Author

THE LINK

Views

4194

Build Author

THE LINK

Views

4194

2020 First build.

Probably cheapest DIY build youl see.

Build Author

JerryD

Views

4463

Build Author

JerryD

Views

4463

1500x1000mm Adjustable Height

I have the demand to cut/etch tall pieces of material. For this reason, I have designed a machine with 500mm uprights with adjustable gantry height. This way I can raise/lower the sled and z-axis as needed. I've also chosen to use a linear C-channel assembly for the Z axis with the plate mounted to the gantry instead of the other way around. This will allow for maximum range of the z-axis. The parts list/BOM does not include motors/belts/pulleys or electronics.

Build Author

M^3

Views

20380

Build Author

M^3

Views

20380

M Cubed CNC Mill

A no-nonsense CNC mini mill to get the job done.

Delta-Six

Super rigid Delta printer, using 20X40 V-Slot

Build Author

evgeny156

Views

6311

Build Author

evgeny156

Views

6311

3D Printer on Prusa architecture with best parts available

Wanna quet an nice looking device done by my hands

Build Author

Limine3D

Views

7519

Build Author

Limine3D

Views

7519

M3D Squared

A cartesian build with a build dimension of 200x200x750mm. I will be using a dual extruder, heated build plate, and a screw drive for the z axis.

Build Author

Steven Sampson

Views

9807

Build Author

Steven Sampson

Views

9807

RiNo Route

A CNC router designed to handle a 4'x8' sheet, for as close to $2000 as possible. The price barrier resulted in my choice to use timing belts rather than leadscrews or rack&pinion. Build List still being updated

CO2 Tube life expectancy experiment - Sponsored in part by Openbuilds

Hypothesis - Running CO2 laser tubes at high amperage may shoirten tube life in number of hours, but will be made up for by the increase in actual inches engraved/cut using the higher power. This is a long term experiment, so the build status will remain as "Build in progress" until the experiment has been completed.

Build Author

Matt Barile

Views

6122

Build Author

Matt Barile

Views

6122

Fixed Gantry Welded Steel Router

Fully welded, fixed gantry CNC router, with chinese linear motion parts, in progress

Live D-bot build at MRRF 2017 (Mar 25-26)

I will be attending the 2017 Midwest RepRap Festival (MRRF) with a small team of printer enthusiasts with a goal to fully assemble a Core-XY D-bot onsite during the event. This is our first attempt at building a D-bot and we will be learning things as we go. Our hope is to have the entire machine assembled, wired, and functional (at least to the setup and testing phase) before the end of the show. Please attend and watch us in person or visit our feed channel during/after the event.

Build Author

Anthony Bolgar

Views

10498

Build Author

Anthony Bolgar

Views

10498

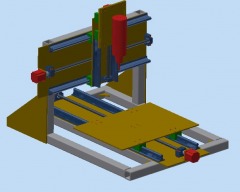

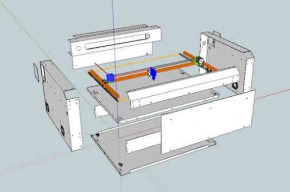

L'FOX - Large Format OX deriviative. Designed and built by Revision 13 Prototypes

This build is for a testing rig to use while testing out different controller boards and CAM software for milling and routing. It is in the early stages, planning is complete, parts are ordered. Awaiting parts delivery to start build. Please not the BOM only covers parts from the OpenBuilds part store. I will be posting the other required items very shortly.

Build Author

DistortedDesigns

Views

32394

Build Author

DistortedDesigns

Views

32394

Project Death Star - DistortedDesigns Laser Engraver

2 watt Laser Engraver, Simple, Fairly Low Cost, and Portable

Build Author

Keteland

Views

9751

Build Author

Keteland

Views

9751

MULIMATERIAL 3D PRINTER (in progress)

ELECTRONICS - ARDUINO Mega 2560 + RAMPS 1.4 + power supply 12V - Leadshine DM 5042 external driver + Power supply 36V + NEMA 23 stepper motor SOFTWARE - Repetier Host to communicate with the Ramps - ARDUINO to upload the firmware (Marlin) MECANIC - V-Slots rails 40x40 + home-made plates - everything goes fine on the side of the build

delta 3d printer kit

HE3D K200 kit build

Build Author

openhardwarecoza

Views

27008

Build Author

openhardwarecoza

Views

27008

openBuilds FreeBURN-2-Mini V-slot CO2 Laser (40-50w)

A new mini version of the http://openbuilds.com/builds/openbuilds-freeburn-1-v-slot-co2-laser-60-100w.1001/ FreeBurn CO2 Lasercutter

Hlidskjalf, CoreXYU (dual X-carriage)

Dual X-Carriage CoreXY. Not impossible, but probably the only one. Use the link to Thingiverse "Hlidskjalf" for parts and downloads.

Build Author

Bridge Port

Views

7600

Build Author

Bridge Port

Views

7600

CNC Line Boring Machine

This is a CNC Line Boring Machine for our cabinet shop. It drills the holes every 32 mm for the adjustable shelf pins in the cabinet side pieces. I chose this option over purchasing a multi-head boring machine that requires 11 drill bits - Left & Right hand twist - that also requires a lot of strength to plunge that many drill bits into the wood to be drilled.

Fun and Functional Laser Build

A very fun and fulfilling build. I can't say enough about the whole Open Builds site and Open Source movement. I strongly believe this is the fastest and most creative way of getting ideas out of the mind, and onto the floor.

C-Beam Big Mouth

My first build was with the basic C-Beam Build. I soon found the z clearance a little constricting So I added 2 500 mm actuators to support the x axis rail . I also left off the front and back y axis support rails for easy cleaning. I mounted the base of the machine to 1/2" mdf with 10/32 screws and blind nuts.

CO2 laser cutter

A build which is based on a metal frame and aluminium plate which I salvaged from a skip. The frame is sized to hold 19" rack units so I'll build my control box into a 3U rack unit (also salvaged). The area available for the build is 700x1200mm. I'll sling a 60W CO2 tube under the base, the beam path will be initially upward into the enclosure.

Build Author

UltiBots

Views

9474

Build Author

UltiBots

Views

9474

Machined Aluminum MagBall Carriages

Machined Aluminum MagBall Carriages

Build Author

Rwetzler

Views

7932

Build Author

Rwetzler

Views

7932

C-Beam Prototype

This is a variant of a typical OX (Mark Carew inspiration) router using C-Beams/8mm Acme rods to drive all three axis. I went with a 1000mm x 1000mm frame size. Useable space is 28" (711mm) X 26" (660mm) with a Z axis work travel of approx. 3.25" (82.5mm). A TinyG is used as a controller along with Fusion 360/Chilipper as the software for generating and running gcode files.

Build Author

Neptunes Guitars

Views

7342

Build Author

Neptunes Guitars

Views

7342

Neptunes Ox

First build of CNC OX for the purpose of using it for Guitar building to take a lot of the muscle work out so I can concentrate on the finer details.

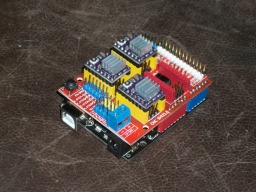

Gargoile reproduction C-Beam™ Machine - Plate Maker

A stock C-Beam with a CNC shield with DRV8825's

Build Author

Sonny Lowe

Views

9760

Build Author

Sonny Lowe

Views

9760

Folger-Tech Y-Carriage

This a redesign of the Folger-Tech Y-Carriage using the Solid V-Wheels, Ball Bearings, the V-Slot Rail System.

Expanded Routy using 290 build instructions

Using the Routy290 build and an awful lot of help from puntoMX, this machine has been expanded in the X and Y axis. My first build, I'm learning a lot about all of this. I've had to disassemble parts of this thing many times due to forgetfulness, but that's ok. Also, I've forgotten to take constant pictures throughout the build.

CO2 laser.

Here it is my intention to show what was involved in adding a CO2 laser to my existing CNC machine.

Build Author

alex_b

Views

14079

Build Author

alex_b

Views

14079

RONIN OX | The G10/Carbon Fiber Hogger

The Ronin OX is a dedicated fiber composite milling machine. I give a complete in-depth article on how to take a nearly stock OX build and easily turn it into something that can mill carbon fiber and G10 plate effectively and quickly.

Build Author

Gary Bonard

Views

5083

Build Author

Gary Bonard

Views

5083

OxZilla

This is my second Ox with a working area of 14" x 14" x 5" I wanted to build a small sturdy potable CNC router and this OxZilla has the nice upgrades !

Build Author

Kyo

Views

11126

Build Author

Kyo

Views

11126

V-Slot Cutting System

A System of 3d printed parts to use along with your projects aluminum extrusion to cut your pieces of v-slot to length manually.

My Little OX

This build has been an educational experience. Software and hardware alike.

McRouter 3 Axis CNC

I wanted to put together a medium size router using PTFE slides from McMaster-Carr. I've had great experience with these slides in long term continuous motion operations in industrial environments.

Build Author

Darren Ditto

Views

9395

Build Author

Darren Ditto

Views

9395

V 1.4 - Bright Box Cartesian Printer - *BUILD PROGRESS PICTURES

Cartesian Printer, 200mm x 200mm x 380mm build area, enclosed, belt and pinion movement, heated bed, Raspberry Pi, Pi Cam, OctoPrint

Build Author

JoeH

Views

6644

Build Author

JoeH

Views

6644

COTSPnP

The COTSPnP pick-and-place machine (PnP) is used to place surface-mount devices (SMDs) onto a printed circuit board and was designed and built exclusively from off-the-shelf (COTS) components, predominantly sourced from OpenBuilds and Actobotics. Its intended use is prototyping and not high rate, high volume production and is capable of precisely placing parts as small as 0402 capacitors and resistors but more importantly, can precisely place components with lead spacing as small a 0.4mm.

Mendal Max 1.5 EX2 - a part of this, a part of that.

I like this design a lot. It's very stable, very strong and with the EX2 enhancements, it prints like a champ.

Linear Rotational Art.

One Linear Actuator covering two dimensions, WHAT!

![80watt Lasercutter, workingarea 105x52[cm], steel frame](https://openbuilds.com/data/article_images/l/6/6014.jpg?t=1513166610)