Build List

Build Author

Andrew Helsel

Views

10856

Build Author

Andrew Helsel

Views

10856

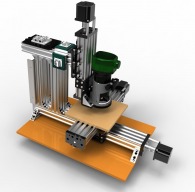

MiniMill Smoothie

MiniMill with DW611 and SmoothieBoard 4x v1.1

Build Author

Joe Young

Views

10842

Build Author

Joe Young

Views

10842

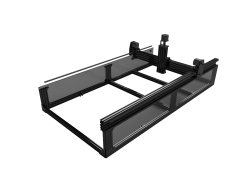

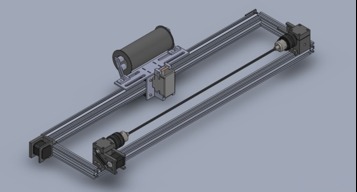

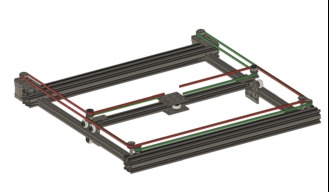

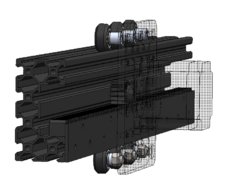

Rack and Pinion (Death to Belts)

Low profile rack and pinion linear actuator design

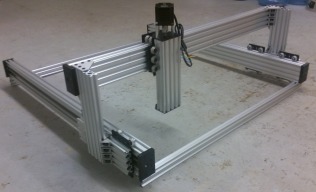

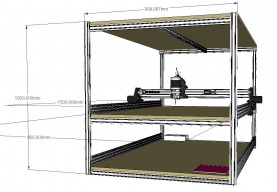

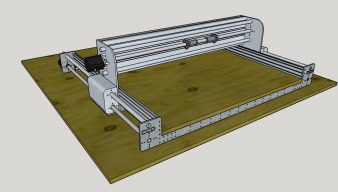

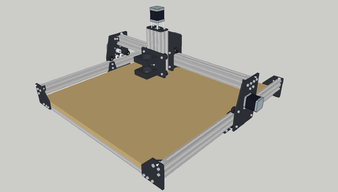

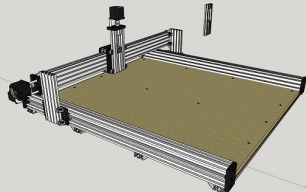

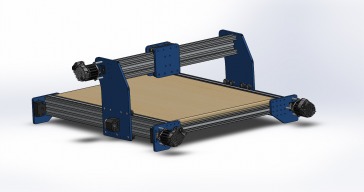

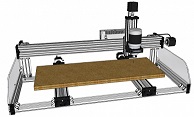

Longhorn OX (Under Construction and In Progress)

I ran across the OX and knew it was the one I wanted to build. Some of the things I wanted to include was make it bigger and a little more solid than what the original plans called for. So here is where I am at so far. It will have a cutting area of 48" x 48". The waste board support frame will have more support rails. The Y axis will have (3) 20mm x 60mm rails instead of the original (2) that is called for. 1/4" aluminum OX plates. And a few more odds and ends.

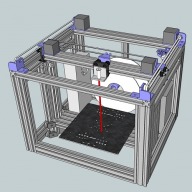

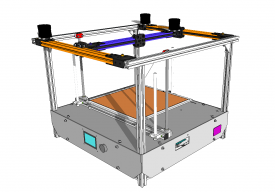

V-rex , Low cost CoreXY

Easy to build,low-cost, CoreXY

Build Author

sw3Dp

Views

10733

Build Author

sw3Dp

Views

10733

stranger than fiction OX

OX hybrid all CAD open sourced non-commercial ip; .dwg, .dxf,.3dm, .iam, .ipt files jamming their pie

Build Author

John J Talavera

Views

10720

Build Author

John J Talavera

Views

10720

CNC FOR EVERYONE TITAN CNC ROUTER

www.cncforeveryone.com TITAN CNC ROUTER is the perfect PCB milling machine or for smaller projects. Don't be fooled by its small size it is capable of routing with the big boys...!

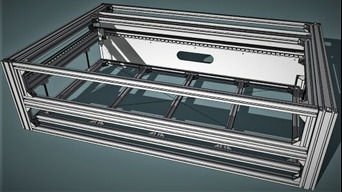

C-Beam XXLarge "Tank"

This is a modified build C-Beam XLarge. 1000mm C-Beam used for X and Y axis, and the Y Axis moves the X bridge, not the material being worked.

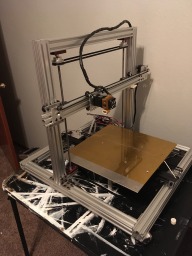

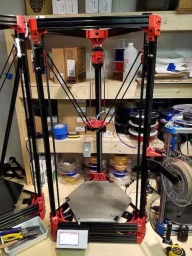

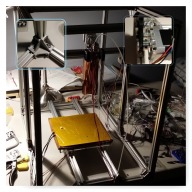

My 1st Build - Delta Printer with 3 filament hot end

The build area will be fully enclosed. I anticipate using primarily ABS, and have interest in the soluble support materials as well. The main components to date include: OPENBUILDS - 3 x C-Beam™ Linear Actuator Bundle, 1000 mm, w/ Included NEMA23 Motor) Extruders (3) - [Sintron] 1.75mm Mini All Metal MK8 Extruder Hot End - reprap diamond Control board - RUMBA Stepper drivers - DRV8825 StepStick Power supply - eTopxizu 12v 30a

Build Author

Martin Bogomolni

Views

10650

Build Author

Martin Bogomolni

Views

10650

Delta-Six ( Jerry426 variant )

Building a Delta-6 variant, using recycled parts from a WolfStock Delta printer.

My giant "WORKBEE" 1750mm X 1750mm by ooznest

CNC MACHINE WORKBEE'S table making

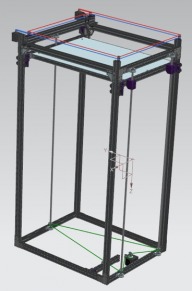

Large 3D Printer 5ft by 5ft print bed

New ultra large 3D Printer design. I'm calling it the AutoCrafter

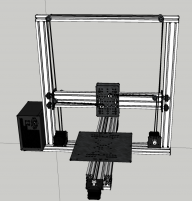

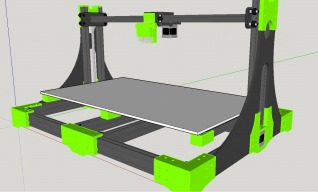

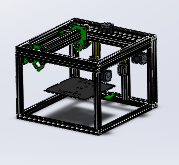

3D PrintBot 500x500x500

Large scale True 500x500x500 build volume 3D printer.

OX, of the house Steel

OOZNEST Style OX machine with 3D printed panels

Build Author

Bud Griffin

Views

10478

Build Author

Bud Griffin

Views

10478

BF3D OX (Big Freakin' 3D OX)

This is my latest printer build. The second printer I've built using V-Slot.

Build Author

jpjoshua

Views

10475

Build Author

jpjoshua

Views

10475

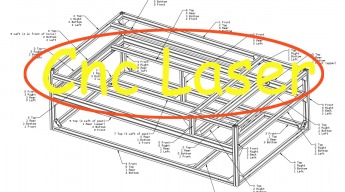

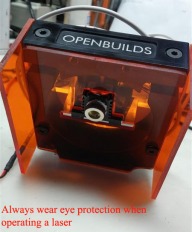

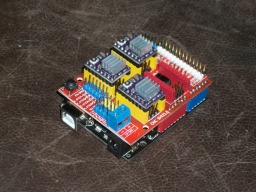

Arduino Grbl Laser CNC

Arduino powered Laser CNC using GRBl firmware.

Polar Bot

Polar Bot which used to depress buttons

Build Author

Anthony Bolgar

Views

10423

Build Author

Anthony Bolgar

Views

10423

L'FOX - Large Format OX deriviative. Designed and built by Revision 13 Prototypes

This build is for a testing rig to use while testing out different controller boards and CAM software for milling and routing. It is in the early stages, planning is complete, parts are ordered. Awaiting parts delivery to start build. Please not the BOM only covers parts from the OpenBuilds part store. I will be posting the other required items very shortly.

Build Author

evil2002usna

Views

10340

Build Author

evil2002usna

Views

10340

Evil Ox

Cheap Ballscrew Ox CNC Router.

Big CNC plasma cutter

more later

Build Author

Venturebit

Views

10271

Build Author

Venturebit

Views

10271

SHRED-Buddy3D UPcycler - Open Source Multi Material Cutter&Pelletizer

The whole system is powered by 12V / DC power. Process it into Pellets or Granules to use it with your 3D Printer or Filament Extruder. Our self-developed steppermotor Controls allows you to optimally adjust Feedrate for your Situation. Forward, Backward and Stop is integrated for easy operation. The Speed can be continuously regulated via rotary switch.

eTrueUp Glide

A TrueUp Glide modified to use 20x40 V-Slot with a 300x300 bed.

Build Author

boubouexpress

Views

10241

Build Author

boubouexpress

Views

10241

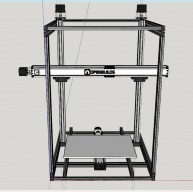

3D Drucker sparkcube V1.1XL V-Slot™ Mini V Linear Actuator Bundle

sparkcube V1.1XL edit V-slot mini v linear

Build Author

obmilllivebuild

Views

10217

Build Author

obmilllivebuild

Views

10217

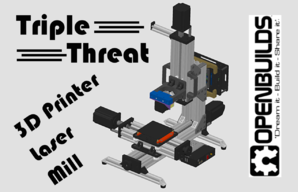

Live OpenBuilds MiniMill -> MiniPrint/Laser Conversion Demo @ MRRF2019

Transformation of an OpenBuilds Mini Mill into a convertible 3D printer / CNC mill with interchangeable tooling. Maybe a bonus conversion TBD.

RoStockFAZZ

My large printer design. 400mm build plate, ~1000mm build height. Most of structure is 8020 but the sliders are V-Rail

Long Ox with drop in table

This build is a modified Ox build. The long rails are 1000mm. My build includes a solid clamping table.

CNC Hotwire Foam Cutter

Here is my first ever CNC build. A CNC Hotwire Foam Cutter. I will update about achievements. I would love to read from you guys - advices, ideas. Especially regarding the electronics. I feel confident with the hardware part which I can't say about the electronics part.

CO2 Tube life expectancy experiment - Sponsored in part by Openbuilds

Hypothesis - Running CO2 laser tubes at high amperage may shoirten tube life in number of hours, but will be made up for by the increase in actual inches engraved/cut using the higher power. This is a long term experiment, so the build status will remain as "Build in progress" until the experiment has been completed.

C-beam Router rack and pinion

I want build a frame that is as sturdy as possibility while at the same time keeping it as compact as possible. working area will be approx 1200mm x 600mm

Build Author

dreys

Views

10090

Build Author

dreys

Views

10090

Was once a mini mill

Working progress.

Build Author

Laurence Carroll

Views

10089

Build Author

Laurence Carroll

Views

10089

C-Beam Double X

Per the special notes its a variant of the C-Beam, Machine.... I have noticed that alot of people build a CNC router to cut parts for other larger CNC machines.. eg Delta Printers etc....plus this will enable me to cut parts for model RC plans UAV's etc...

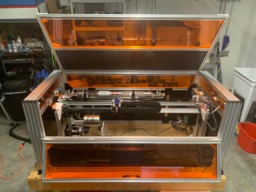

Laser cutter

In the expo projects during the second year of engineering students. the project group who made this rapport made a laser cutter for the students of Fontys Hogeschool Engineering to use this machine for creating parts for their projects. The goal of Project Laser Cutter is to build a laser cutter, which is safe and can be used within the school. Also it has to be able to cut through 10 millimetres thick acrylic material or 10 millimetres thick plywood. This project will follow the V-model. This

STEAM crane printer

The STEAM Crane 3d printer uses the new C-Beam linear rail. It is being developed for an after school / summer camp program for kids. All of the electronics are housed in the base and the wiring is routed down the channels of the c-beam. This is done to contain as much of the loose wiring as possible, hopefully keeping it safer for kids.

Extendable Mini Mill

Another MiniMill, different to the OpenBuilds version and potentially more flexible because of the design.

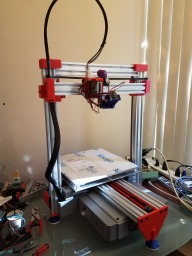

Ez3D - Phoenix 3D Printer Build

This is my 1st submission to openbuilds.com and my 1st venture into building a 3D Printer. The Phoenix 3d Printer is a kit from Ez3D, a company based out of Colorado, started and backed by successful Kick-starter and IndieGogo campaigns. The Phoenix 3d Printer kit is currently backlogged 10 to 12 weeks which means quite a wait. I will be chronicling my experience with this kit as I get it done.

Photogrammetry 3d Scanner

A mid-sized version of a Photogrammetry 3D Scanner.

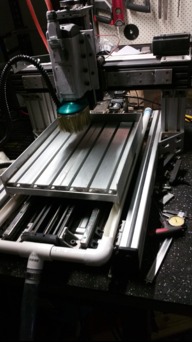

The Hoss

The purpose of this build is to create a simple, strong modular build that is rugged enough to cut out some of the softer metals along with wood and plastics. Using basic parts like the universal plates, t-nuts and v- wheels coupled with the strength of C-Beam I am sure this will deliever the desired results!!

The Franken Rotor

Yes another K40 Franken machine dedicated for round objects,,,

Build Author

Bear

Views

9800

Build Author

Bear

Views

9800

OXBear

ANOTHER OX!~ Huge Thanks to Marc Carew and Open Builds. The primary reason I am building this CNC mill is to aid in my homemade snowboard creation. I am going to try and document as much of everything as I can and post it here to help others going a similar route. I know from past projects that taking the time to document each step can be tedious when you want to charge ahead but I will try! I hoping to get feedback on my design choices and set up as I am a complete newbie to CNC.

cnc plasma table

ive got most of the wire harness made up too im using Chinese electronics for now I will upgrade later when this thing makes me some cash lol im using a ibm think center to case to hold my electronics ive got a 25' parallel cable to put some distance between the table and the computer

Makerparts.ca Prusa i3Pro 300

Concept for a Prusa i3 made from Cbeam Extrusion. X & Y using GT2 Belts, Z using Acme Screws Goal is to build a simple. and very Solid Printer Single Z Motor to keep the Z Screws in Sync. (Might require Geared Nema 17) 12" x 12" x 12" Build volume Nema 17's

Build Author

dcarlisle

Views

9744

Build Author

dcarlisle

Views

9744

pain in my ox

build is in process the machine went together perfectly no issues at all but the software is another issue I have been trying to get the thing dialed in it is driving me nuts I'm still in the process will update if I ever get it figured out

Build Author

Keteland

Views

9709

Build Author

Keteland

Views

9709

MULIMATERIAL 3D PRINTER (in progress)

ELECTRONICS - ARDUINO Mega 2560 + RAMPS 1.4 + power supply 12V - Leadshine DM 5042 external driver + Power supply 36V + NEMA 23 stepper motor SOFTWARE - Repetier Host to communicate with the Ramps - ARDUINO to upload the firmware (Marlin) MECANIC - V-Slots rails 40x40 + home-made plates - everything goes fine on the side of the build

TABLE OX Router/3D-Printer

OX MultiMachine

Filament winder ( carbon fiber )

Carbon fiber filament winder

Build Author

Kyo

Views

9607

Build Author

Kyo

Views

9607

Fina

This is Fina; My Lautr3k inspired build.

Genesis XZ

CoreXZ implementation on 3d printer using Openbuild and RobotDigg parts.

Open Rail Build

This will be a chronicle. It's my first CNC build so, I will be making many changes as I learn from my mistakes. I will pass on any tips or tricks i learn along the way. This build is an OX Hybrid. I decided to use the open rail with the V wheels and not to go with the V Slot. (I'll let you know how it works out.)

Large format plasma ox

I will update this as I go, cad files upon request. My x beam is basically a belt driven r7

InDoreXY

A Large CoreXY build that can just barely get in through a doorway, aiming for under $1000. Build Volume approximately 18in x 24in x 26in.

Build Author

UltiBots

Views

9419

Build Author

UltiBots

Views

9419

Machined Aluminum MagBall Carriages

Machined Aluminum MagBall Carriages

Build Author

Kaarbble

Views

9411

Build Author

Kaarbble

Views

9411

Kaarbble Nylon Bot

We plan experiment on nylon 3 D printing;

C-Beam bellows

Making a bellows to cover a C-beam to prevent swarf from gumming up the works.

60W CNC Laser build

Laser CNC, 60W, didn't have one yet... have to :) This build is a retrofit of a surgical laser into a CNC.

Draw bot core xy

In the design stage. Help guide.

Versabot - All metal 3D printer

An all metal construction cartesian style 3D printer with a very rigid frame that has the flexibility to function as a desktop milling station or laser cutter with appropriate user designed attachments. Design is scaleable to suit any size requirement. All axis are leadscrew driven. V-Slot and Mini V-wheels have been utilised for the linear rails.

CO2 laser

http://www.buildlog.net/sm_laser/drawings.html using this as a baseline.... Going to try and use all or most off the shelf parts.

Build Author

Darren Ditto

Views

9273

Build Author

Darren Ditto

Views

9273

V 1.4 - Bright Box Cartesian Printer - *BUILD PROGRESS PICTURES

Cartesian Printer, 200mm x 200mm x 380mm build area, enclosed, belt and pinion movement, heated bed, Raspberry Pi, Pi Cam, OctoPrint

ALUMNO v1

It is a first draw of my future Printer/CNC cutter.PCB mill Still need to work more on it

Behemoth cnc router with linear rails

Behemoth cnc router build in progress using hiwil rails and closedloop servos.

Build Author

Glenn Weston

Views

9184

Build Author

Glenn Weston

Views

9184

"AcroCadabra" My Acro Laser built with my C-Beam XL

Well I built a C-Beam XL around a year ago, I am still learning things as I make stuff with it, it has been quite a wonderful learning experience. Now I have gained enough confidence and knowhow to Mill the required Plates to build an Acro Laser System using the Acro Laser Sketchup Model. I have pulled the Model apart in Sketchup, isolated the Plates and generated the G-Code to cut/Mill the plates. I have used Sketchucam to generate the G-Code. I Use Mach3 on my C-Beam XL to Mill.

3 Axis MultiTool - 3D printer, CNC Mill and Plasma Cutter

So in short this build is a work in progress; it aims to make a large 3d printer, medium size CNC mill and a small plasma cutter all in one CNC unit.

Large Volume 3D Printer

. .

Build Author

Philippe Bergeron

Views

9137

Build Author

Philippe Bergeron

Views

9137

My first 3D printer: Absolute3Dr

You are about to read the evolution of my 3d Printer build.

W|W plasma/drag knife 1500x1500 (floating head & z-axis)

Step by step designing and implementing of my plasma approach

OX-LX-3D

An OX build - little large than specs and plates 3D printed

Rex

This build is inspired by the Lulzbot Taz printers and makes use of the new OpenBuilds C-Beam

KRE CO2 2x4 Laser

Large Format CO2 Laser Cutter

Viking OX

My OX cnc upgrade.

Hybrid OX (Ball Screw, Linear Guides, Ect.)

Planning my first build. Hope to achieve a larger format yet rigid design.

BldrBox

OpenBuilds box type printer using min-v-wheels for X & Y axis. Designed for plexiglas panel enclosure of build area.

Build Author

Jason @ MCC

Views

8912

Build Author

Jason @ MCC

Views

8912

QueenBee Pro CNC Router and Lathe

A 1000x1500mm QueenBee Pro with a 4th Axis Rotary attachment/Lathe Bed.

Laser Mount

This is a mount I wanted to build for a laser project using OpenBuilds part router mount.

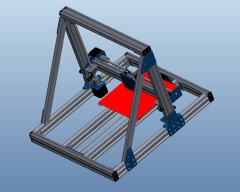

A very affordable CNC routing

In progress CNC, (just design for the momment), I want to get some feedback about the design and the possible flexion of the aluminum profiles chosen

Arctic Ox CNC Router

This is a cartesian CNC Router build that is based off the OX CNC build by Mark Carew. I am using Spark Concepts CNC xPro controller board and their 400w spindle kit.

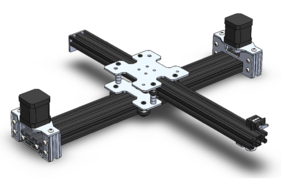

All Metal - CoreXY Motion

Stacked CoreXY Motion System using only Openbuilds components

OX Build

Standard OX Build

Build Author

crypt-tek

Views

8766

Build Author

crypt-tek

Views

8766

crypt-cube

The crypt-cube is another project I've been working on off and on over the past year, unlike my previous built C3DO this is a much smaller built with a volume of 318mm x 240mm x 220mm. With this build my main focus is precision and speed.

Build Author

Rob Taylor

Views

8758

Build Author

Rob Taylor

Views

8758

Grizzly G0758 Benchtop Mill Conversion

A proper CNC mill conversion. But quite small, with my trademark idiosyncracies.

Powder coated multi CNC Z Axis plasma adapter with Prox.

Powder coated multi CNC Z Axis plasma adapter with Proximity sensor. . It can also hold a 80mm Router head/Spindle as seen in my router build.

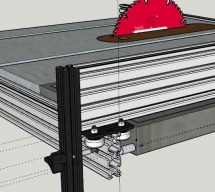

Table Saw Fence

Trying to build a low cost table saw fence using v-wheels

Build Author

COMsulting

Views

8638

Build Author

COMsulting

Views

8638

1x1 Meter Laser Engraver

Building of a big open frame laser engraver.

Build Author

Asaku

Views

8620

Build Author

Asaku

Views

8620

mBOX

Hi! This build is, or at least should be, a multipurpose box (mBOX). Due to limited space I want to build something that can serve multiple purposes such as 3d printing, 3d scan, plexiglass cutting and hopefully some milling too (both wood and metal). Switching between modes should involve switching heads and worksurface (change heatbed with a wood platform and viceversa). (for the scan part I'm thinking of integrating this opensource project into the frame: http://www.freelss.org/ )

TrueUp LZ

A version of TrueUp using linear bearings/rods for the Z axis. This required enough modification to make a separate OpenBuilds project to avoid confusion for DIYers.

Gargoile reproduction C-Beam™ Machine - Plate Maker

A stock C-Beam with a CNC shield with DRV8825's

Build Author

pedrofernandez

Views

8548

Build Author

pedrofernandez

Views

8548

K40 Cube Laser Cutter

The k40 cube is a laser cutter build using mostly stock parts of the chinese k40 laser

The Budget Build

An affordable large CNC machine, that so far has been easy to assemble

V-Slot Workbench

A Workbench idea built from V-slot and openbuilds parts.

Build Author

Superslinky

Views

8496

Build Author

Superslinky

Views

8496

K40 Laser Build (Major Changes)

Major K40 Laser Mod

C-beam Camera slider

feel kind of bad calling this a build because of pretty much everything is off the shelf parts. I'm writing my own sketch right now for the motion but there is a version or 2 floating around on the net based of this design. I will post my code once it's done.

Kool Bot

Mid range build.

(Smaug) 100w 1500x1000mm CNC Laser

Laser CNC made with mostly Openbuilds and amazon sourced components. Lots of 3d printed components as well. The main purpose is to cut EVA foam.

Build Author

Christer Langley

Views

8436

Build Author

Christer Langley

Views

8436

CNC-Solutions Build

My first Build with V-slot

Beaver's OX 1500

OX 1500mm x 1500mm w/1.5Kw Water Cooled Spindle & VFD ran by a Gecko G540 & Mach3

Y-1200 co2 laser

Y-1200 Build The Y-1200 has a cutting area of 1200 x 600mm and the main chassis has a external size of 1620 x 955 x 450mm. The recommended power output is 60-90W, this can also be increased with the use of an extension box. designed by furtherfabrication ROB CHESNEY FREELANCE INDUSTRIAL DESIGNER.

ACRO 150 X 150 CM

Openbuilds ACRO

Build Author

Mike Andrews

Views

8345

Build Author

Mike Andrews

Views

8345

Monster - a multiple material 3D printer with 20"(X) X 14"(Y) X ~20"(Z)

A Laut3k derivative that goes for volume and large number of print materials at the same time. Using OpenBuild linear motion systems to get away from belt drives.

Table saw fence and guide

The idea was to build a proof of concept table saw fence similar to a thru-rip or accusquare fences which retail for 400$, with the added option to motorize the positioning.

Large 3D printer

Hello ! This is my very first OpenBuilds build. It's based on the Maximus 3D Printer, published by mytechno3d : good source of inspiration !

Build Author

Sword66

Views

8292

Build Author

Sword66

Views

8292

The Archon R2

The Archon "In the style of Cartesian movement." A brief overview, guide and summary of my highly experimental build. and some insight into the challenges of building such a large format/belted machine.

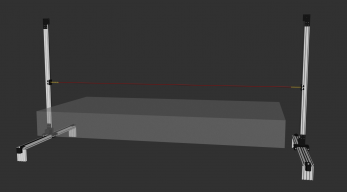

Laser cutter project by students

This build is made by students from Fontys Hogescholen Eindhoven, department Engineering. Every quarter a new group continues the work of the previous group. We have been working on the project since september 2015, and as it is a work in progress, a lot will be added later. The first months have mainly been about designing and building an XY-table on which later all the electronic components will be added and the laser.