Build List

-

Active Filters:

lead

Build Author

Quentin Karmark

Views

5389

Build Author

Quentin Karmark

Views

5389

Laguna Swift 4X4 CNC mill retrofitted with OpenBuilds

Used Laguna Swift 4X4 CNC mill with Water-cooled Spindle and RichAuto serial pendant retrofitted with OpenBuilds/Blackbox/Interface

Build Author

StrictlyScale

Views

6350

Build Author

StrictlyScale

Views

6350

Lead1010 Build with Enclosure

First time CNC builder puts together a Lead1010 machine.

Lead 1515 tilting table and vertical table accessory

I wanted a CNC machine that was able to do dovetails and other box joints. I also wanted to have it be able to tilt so it would take up less space when I was working on other projects.

Build Author

Mark Carew

Views

57080

Build Author

Mark Carew

Views

57080

V-Slot NEMA 23 Linear Actuator (Lead Screw)

Learn to build a super strong nema 23 lead driven linear actuator

Build Author

Frank Del Favero

Views

5112

Build Author

Frank Del Favero

Views

5112

Portable self-contained Lead 1010 table

I have a two car garage NOT devoted to 3d printing or CNC. I have set aside a space for my 3d printer and a place to store my portable CNC table. The reason it’s portable is so that I wheel and can use my Lead 1010 outside where it won’t make a mess in the garage. The table is self contained. It houses a vac system as well as my CNC tools and supplies.

Build Author

Mark Carew

Views

177404

Build Author

Mark Carew

Views

177404

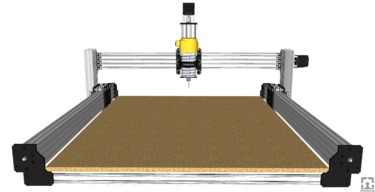

LEAD CNC 1010 (40" x 40")

The OpenBuilds Lead Machine takes us back to the roots of the OpenBuilds modular building system, and has proven itself as an adaptable design that can compete with any machine in its class!

Build Author

Mark Carew

Views

27868

Build Author

Mark Carew

Views

27868

High Z Mod for Lead CNC

The High Z modification for the LEAD CNC brings your creative capabilities to new heights! With 8" of clearance this modification can be adapted easily to your existing LEAD CNC Router.

Build Author

OpenBuilds

Views

12113

Build Author

OpenBuilds

Views

12113

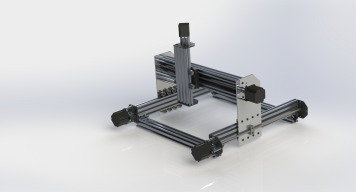

C-Beam® Tension XL Linear Actuator

Bringing your lead screw precision and accuracy to new lengths using a simplistic tension system!

Build Author

OpenBuilds

Views

18014

Build Author

OpenBuilds

Views

18014

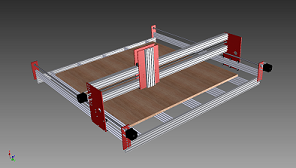

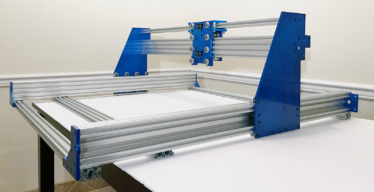

OpenBuilds Table Series

The OpenBuilds Table Series offers a modular table structure that grows with your needs.

Build Author

Mark Carew

Views

67967

Build Author

Mark Carew

Views

67967

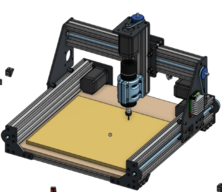

OpenBuilds Workbee 1010 (40" x 40")

The OpenBuilds WorkBee 1010 - 1000x1000 Lead Screw Driven CNC Machine

Build Author

Jason Moore

Views

9800

Build Author

Jason Moore

Views

9800

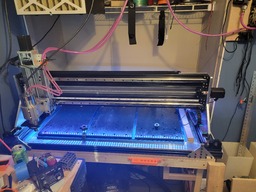

Lead1500 Plasma Table w/THC

lead machine plasma table with Black Box, and Torch Height Control

Build Author

OpenBuilds

Views

3175

Build Author

OpenBuilds

Views

3175

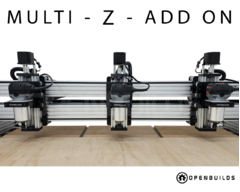

Multi Z LEAD Machine Addon

The Multi Z adds multiple Z axis to a LEAD CNC Machine allowing it to cut and carve 2 to 3 times the amount of projects in the tame it takes to make just one

Build Author

Ted Moyer

Views

3590

Build Author

Ted Moyer

Views

3590

LEAD 1515 HIGH Z MOD 4KW ER20 7.5 KW VFD

OLD Lead 1010 High Z Mod converted to Newest Lead 1515 with High Z mod, slimmer cbeam motor mounts, thrust bearings etc. Extended by original table out and upgraded my 1.5kw VFD and Spindle to 4kw ER20 Spindle and 7.5kw GT VFD

Lead 1010 First time build

First time build of the Lead 1010 CNC with the High Z add on.

Build Author

Jasont

Views

2405

Build Author

Jasont

Views

2405

MY first CNC build

my first cnc build using the lead 1010 to build bigger and better!!

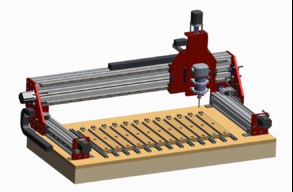

ACME OX (A Lead Screw Driven Ox Derivative (850x1500))

Another build based on the original OX design with a cutting area will be about 26" (680mm) x 50" (1300mm) and driven by lead screws.

Build Author

Jay Almers

Views

6205

Build Author

Jay Almers

Views

6205

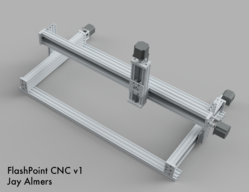

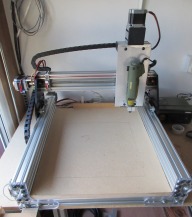

FlashPoint CNC v1: 500mm x 1000mm 3-Axis CNC Router

My build is based on many different builds but pieced together into a unit specifically to suit my needs. The footprint, without motors, is around 500mm x 1000mm with a gantry height of around 250mm. I used a combination of C-Beam, for the linear transmission, and V-Slot for the base and gantry supports. Forged angle connectors were used for attachment and I utilized the C-Beam gantry cart kits with anti-backlash blocks for both Y axes, the X axis, and Z axis.

Build Author

sgspenceley

Views

181836

Build Author

sgspenceley

Views

181836

Linear Rail CNC Machines

A CNC build using linear rails & lead screws.

Build Author

Shaun Weitzel

Views

4620

Build Author

Shaun Weitzel

Views

4620

OpenBuilds Lead 1515

First build of a Lead 1515!

OB Lead 1515 CNC Router 2021

Building the OB Lead 1515 was straight forward. The on-line OpenBuilds assembly videos were extremely clear and easy to follow. Initial build of this machine is with OpenBuilds BlackBox which simplified getting the electronics to work the first time. OpenBuilds staff are friendly and helpful.

Build Author

nickchnv

Views

9870

Build Author

nickchnv

Views

9870

Rigid Compact Desktop C-BEAM

This modified C-Beam, is a compact, powerful and affordable desktop CNC.

Build Author

Mark Carew

Views

76343

Build Author

Mark Carew

Views

76343

OpenBuilds Workbee 1510 (60" x 40")

The OpenBuilds WorkBee 1510 - 1500x1000 Belt Driven CNC Machine

Lead 1510

Customised Lead 1010 making it a 1510. T-Track work area with dual Y limit switches for auto-squaring. Powered by xPro v5 & CNC.js

LEAD 710 with High Z mod

Overview of a 700mm x 1000mm machine based on the LEAD design and with the High Z mod from the start. Will have a parts list you can use to build yourself if you like the formfactor

Build Author

shanehooper

Views

25268

Build Author

shanehooper

Views

25268

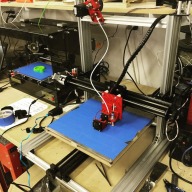

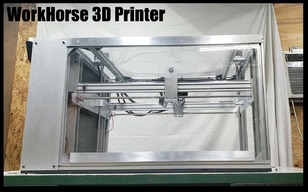

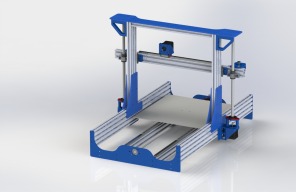

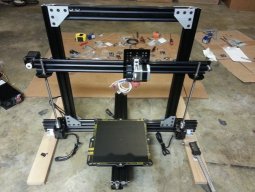

Workhorse 3D Printer

Large 600mm x 350mm x 350mm Build Volume with lead screw driven motion. The printer build has a moving gantry and fixed heat bed. Open Source

Build Author

Mark Carew

Views

46822

Build Author

Mark Carew

Views

46822

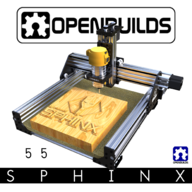

OpenBuilds Sphinx 55 (20" x 20")

The OpenBuilds Sphinx 55 - 500x500 Lead Screw Machine

Build Author

Marshall Peck

Views

78539

Build Author

Marshall Peck

Views

78539

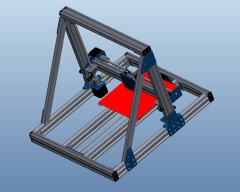

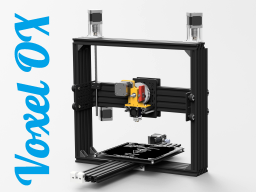

Voxel OX - Extendable 3D Printer and CNC Platform

An open source 3D printer design with a sturdy V-Slot frame

Build Author

ckgottabuild

Views

2523

Build Author

ckgottabuild

Views

2523

Lead CNC 1010 Platform and Rotating Laptop Mount

Moveable Lead CNC1010 build with handles on four corners. Everything fits on one sheet of cut out 4x8 plywood

Build Author

Stokrotka74

Views

5522

Build Author

Stokrotka74

Views

5522

Racoon CNC

This is a Sphinx variation, aimed to minimize footprint and maximize workarea. Work in progress.

Build Author

Mark Carew

Views

19332

Build Author

Mark Carew

Views

19332

C-Beam® XLarge Linear Actuator

This OpenBuilds C-Beam XL actuator is the backbone of a lot of the awesome builds put together by the OpenBuilds community

Build Author

C-CNC

Views

12141

Build Author

C-CNC

Views

12141

Gantry Style CNC from plywood

I am currently 15 years old, from Germany and trying to build a low budged CNC router. I only designed this CNC based on other CNC routers that I have seen and what I am able of. It consists mostly of 2.3cm plywood to keep costs down. The size of the work area is approx. 40 x 80 cm. I would be really glad if you could give me advice's for improvement on the design and everything else ... ( I could really need your help :) ) enjoy :)

LEAD CNC 1010 Laser Modification

Easy All-in-One Laser and Mounting Kit for your Openbuilds CNC.

Build Author

Mark Carew

Views

101901

Build Author

Mark Carew

Views

101901

V-Slot® NEMA 17 Linear Actuator Bundle (Lead Screw)

Example model of lead screw driven actuators for your next project!

Bored in the garage enclosure build

2 days to build Up and running some EMI issues but I think I have them resolved Big shoutout to the community

Yet Another LEAD CNC Build

My take on the LEAD CNC build. Followed the instructions and I think it came together very nicely. Added a few of my own touches to finish up the build.

Build Author

Forestbird Originals

Views

3679

Build Author

Forestbird Originals

Views

3679

Lead 1010 Build - Anything but stock.

This is a lead 1010 build that I wanted to have a little fun with. I purchased the whole Lead 1010 kit, and felt like studying a few shortcomings of the original to see if I can improve it or just have some fun with it.

Build Author

Neil Scott

Views

1841

Build Author

Neil Scott

Views

1841

Barcelona Build

This will be my second CNC build but this time a proper CNC not a small desktop model that I played with for a while to learn Gcode, It was great but now its time to start playing with the big boys and girls.

Build Author

Mark Carew

Views

28651

Build Author

Mark Carew

Views

28651

OpenBuilds Sphinx 1050 (20" x 40")

The OpenBuilds Sphinx 1050 - 500x1000 Lead Screw Machine

Build Author

SecretSpy711

Views

19590

Build Author

SecretSpy711

Views

19590

RigidOko

Heavily upgrading my 1200x500 Shapeoko 2... ...er, wait, scratch that... Building an all new machine, roughly the same size, that should be more rigid than a Shapeoko 3!

Build Author

Mark Carew

Views

10272

Build Author

Mark Carew

Views

10272

C-Beam® Double Wide Gantry Actuator

This easy to build actuator is configured to have not only strength, but accuracy! This low profile option offers endless possibilities, and we cant wait to see how this actuator is implemented in your build ideas!

Build Author

Mark Carew

Views

24137

Build Author

Mark Carew

Views

24137

OpenBuilds Workbee 1050 (40" x 20")

The OpenBuilds WorkBee 1050 - 1000x500 Lead Screw Driven CNC Machine

BKE Lead 1010 - First CNC Router

LEAD CNC

Build Author

recoush

Views

7391

Build Author

recoush

Views

7391

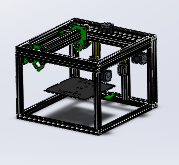

CoreXY 3D build one

an 8020 build with 1010 extrusion (1") Square tubing Rough size is 24x24x36 (600x600x900) The expected usable print area 21.5x21.5X32"roughly (510x510x760) An XY 3D printer with 3 extruders and 3 Z-axis 0.9 degree motors the table (Z-AXIS) will lift up to the XY Carriage on 3 12mm linear rod and 3 8mm Lead screw's Corexy designs complete and Z-axis build is started don’t have a 3D cad system yet so building my prototypes on a pcb layout tool

Build Author

MarkM_NJ

Views

18480

Build Author

MarkM_NJ

Views

18480

Spartacus Inspire

My very first openbuilds cnc machine. Followed along DaztheGas's Spartacus build.

Lead CNC build, Mansfield, Texas - BUILD COMPLETED WITH REVIEW OF THE KIT

The machine is a stock Lead CNC, with the Black Box controller and StepperOnline 269oz NEMA 23 motors. I'll be using the DeWalt 611 from Openbuilds, as well.

OpenBuilds LEAD Machine 1010 40" x 40"

Openbuilds LEAD machine 1010 build

WorkLead, no wait, LeadBee, naw... WoodWorker

Improvements on the Lead machine using some Workbee parts

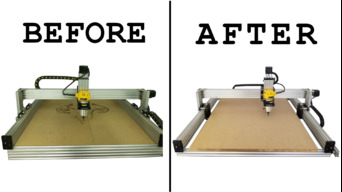

CNC Router Overhaul

This will be a complete overhaul of this router with some cool modifications.

Build Author

Christian James

Views

7191

Build Author

Christian James

Views

7191

Workbee "style" 1010 cnc

This build is based on the Workbee 1010 CNC. It is not a kit build and is much the same as the original but with some significant changes made here and there as the build progresses.

Build Author

Savvas

Views

13181

Build Author

Savvas

Views

13181

Halloumi CNC Machine - Acetal Plates

I built the original machine using plywood plates, and always intended to upgrade those parts to more durable ones. I decided to go with acetal as it's a lot easier to cut than aluminium. I used fusion 360 to model and rebuild the original machine. Once I have assembled everything and feel confident it all works I will release the plate designs here.

Build Author

Colin Russon

Views

8069

Build Author

Colin Russon

Views

8069

OX / X3 CNC / Similar Z axis / 1605 Linear Actuator

Z axes 1605 ballscrew, a comparative design proposal.

Build Author

TimVukman

Views

3340

Build Author

TimVukman

Views

3340

Unique Z

My original Tevo Tarantula kit was ok..... I had issues with the X gantry staying level. I got rid of the wheels and replaced them with linear block bearings. I still had some issues with the X gantry. I swapped out the plastic parts with aluminum which was much better. Still not what I want yet

Lead screw printer

High quality e3d parts with a minimalist design

Build Author

M^3

Views

20300

Build Author

M^3

Views

20300

M Cubed CNC Mill

A no-nonsense CNC mini mill to get the job done.

Build Author

sgspenceley

Views

6361

Build Author

sgspenceley

Views

6361

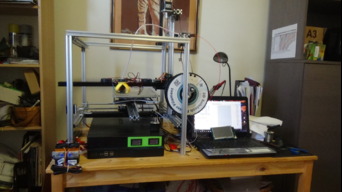

LinearRail - 3D Printer

I have re-purposed many of the parts from my Linear OX build. I'm using MGN 12 linear rails on all three axis, 5 start lead screws on the Z axis and I'm going to experiment with 5 start lead screw on the X axis. The frame plates are made from 1/8" laser cut mild steel, & open builds extrusion.

Build Author

evgeny156

Views

6262

Build Author

evgeny156

Views

6262

3D Printer on Prusa architecture with best parts available

Wanna quet an nice looking device done by my hands

Build Author

mikev

Views

7379

Build Author

mikev

Views

7379

C-Beam Evolution MkII

The C-Beam Evolution is an evolving machine. The MkII is inspired by Kyo's C-Beam Spinx but currently uses my own design of plates made of 8mm acrylic (X-axis ends) and 6mm polycarbonate (Y axis ends). The plates were made on the MkI but I hope to be able to make 6mm aluminium plates on the MkII for the MkIII.

Build Author

adamcooks

Views

41810

Build Author

adamcooks

Views

41810

Triple C-Bot

Based on the work of Carl Feniak and his C-Bot. A robust Core XY style 3D printer that has a clean parallel belt implementation and whose dimensions are adaptable to meet builder's needs. The use of open builds V-slot and other open hardware make customization easy. Utilizing a 300x300 build plate this derivation utilizes three lead screws, synced to a single motor via gt2 belt

Build Author

Keteland

Views

9699

Build Author

Keteland

Views

9699

MULIMATERIAL 3D PRINTER (in progress)

ELECTRONICS - ARDUINO Mega 2560 + RAMPS 1.4 + power supply 12V - Leadshine DM 5042 external driver + Power supply 36V + NEMA 23 stepper motor SOFTWARE - Repetier Host to communicate with the Ramps - ARDUINO to upload the firmware (Marlin) MECANIC - V-Slots rails 40x40 + home-made plates - everything goes fine on the side of the build

Build Author

Steve B

Views

14519

Build Author

Steve B

Views

14519

OX PPR - Portable Plasma/Router

PPR = Portable Plasma/Router. A ~30x30"work area with leadscrews. Work surface is below support members. Can be placed ONTO cutting surface.

Build Author

Philippe Bergeron

Views

9129

Build Author

Philippe Bergeron

Views

9129

My first 3D printer: Absolute3Dr

You are about to read the evolution of my 3d Printer build.

Build Author

Simon Rafferty

Views

6423

Build Author

Simon Rafferty

Views

6423

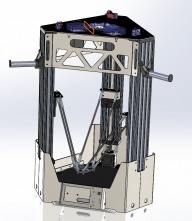

Rigid Delta

A Rigid Delta Printer using C-Beam screw actuators

Versabot - All metal 3D printer

An all metal construction cartesian style 3D printer with a very rigid frame that has the flexibility to function as a desktop milling station or laser cutter with appropriate user designed attachments. Design is scaleable to suit any size requirement. All axis are leadscrew driven. V-Slot and Mini V-wheels have been utilised for the linear rails.

Build Author

Kyo

Views

9596

Build Author

Kyo

Views

9596

Fina

This is Fina; My Lautr3k inspired build.

Build Author

Cuong Vu

Views

31456

Build Author

Cuong Vu

Views

31456

3D Printer

It took me 18 long nights to build it

The MULE (an OX inspired 3-axis CNC)

The Mule is a 3-axis CNC inspired by the OX CNC by Mark Carew. This machine borrows the OX's sturdy frame and upgrades the X and Y linear actuators through the use of three 500mm lead screws (as opposed to the belt system of the OX). The result is an inexpensive, sturdy, and powerful design built for cutting tough materials such as aluminum.

OX 1500x1500 Dual Drive

Ox inspired 1500 x 1500 CNC with belt and pinion drive and lead screw drive options.