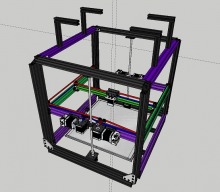

H-Bot CoreXY Cube with Fixed Build Plate-

Discussion in '3D printers' started by TomH, Apr 3, 2015.

H-Bot CoreXY Cube with Fixed Build Plate

Discussion in '3D printers' started by TomH, Apr 3, 2015.

Use of V-Slot for frame and rails with option to use identical 500mm uncut lengths: 8 * 20x60 x 500mm 8 * 20x40 x 500mm 7 * 20x20 x 500mm (2 cut into four identical 125mm pieces for filament holders) Use of uncut 500mm rails obtained through use of 12 joining plates for use as spacers. Alternate approach is to trim two 20x40 and 1 20x20 rail by 6-8mm each. Build volume ~400mm cubed (with dual extruders). Use of only openbuilds components! Currently in design phase...

Page 3 of 4

Page 3 of 4