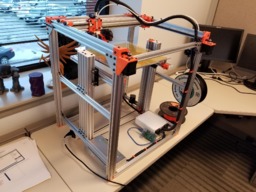

Double D-Bot 400mm x 400mm x 600mm

Discussion in '3D printers' started by Troy Proffitt, Nov 30, 2016.

Double D-Bot 400mm x 400mm x 600mm

Discussion in '3D printers' started by Troy Proffitt, Nov 30, 2016.

Based on D-Bot but used more metal bracing / openbuild plates instead of plastic parts. Also size was increased.

Page 1 of 3

Page 1 of 3