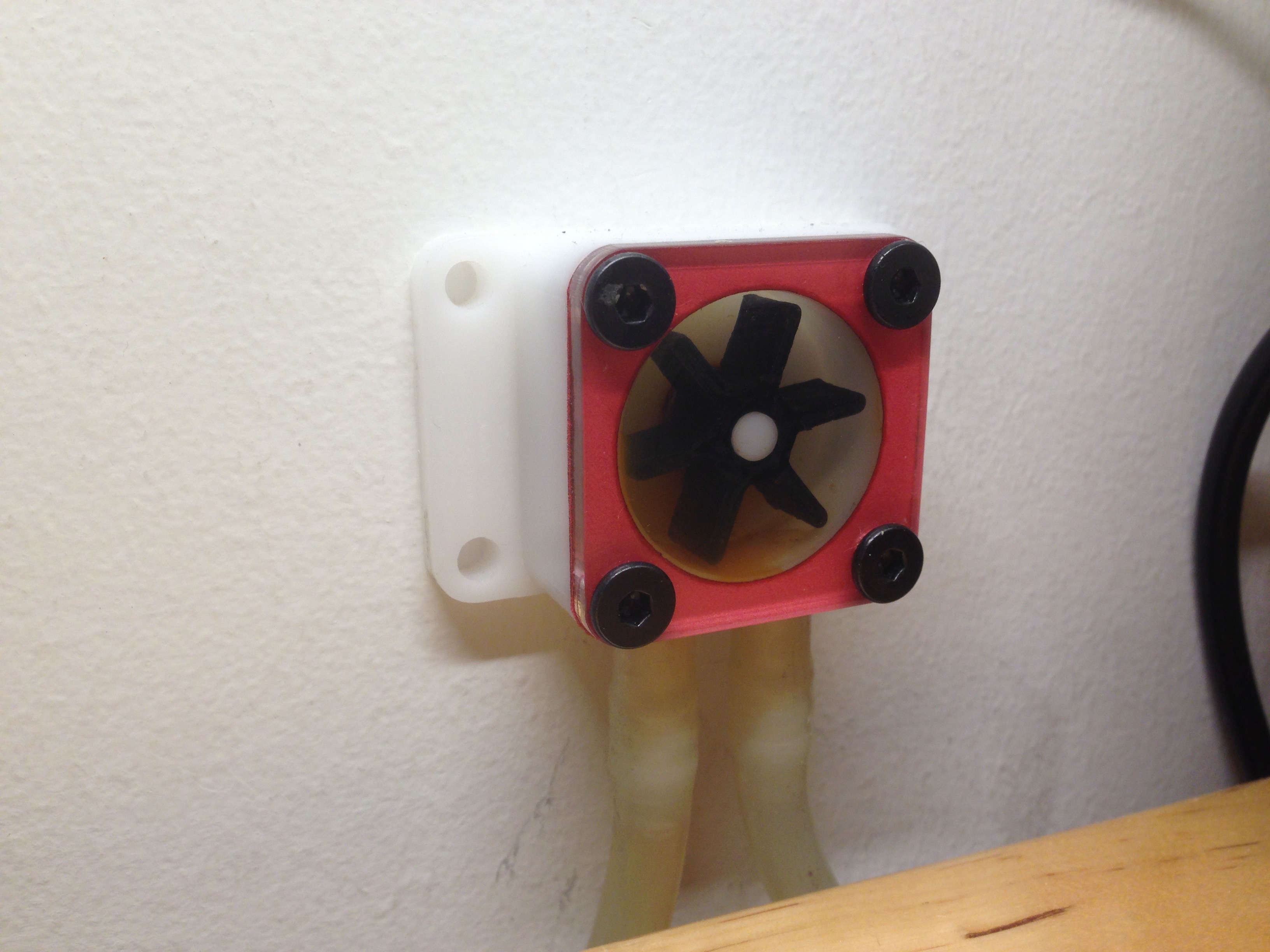

I designed this for my Gen-4 Full Spectrum Hobby Laser. I wanted to be able to monitor coolant flow and didn't like the larger version sold on the likes of Amazon. This pretty compact, and uses pretty standard "maker" tools and materials. I think it could all be 3D Printed even though I CNC Machined the body (two setups). It was a quick little project only taking a couple hours to complete. The barbs for the two coolant connections are press if plastic double barbs, I believe they were Ø0.250". Make the two holes the size required to press in one side of the barb, leave the inside portion long as it can be trimmed to fit the inside hole perfectly

- Machine Type:

- Other Machine

- Machine Time:

- Various, total fabrication time about two hours

- Bit or Laser Size:

- 1/8" Single Flute End Mill

- Feeds & Speeds:

- Sorry, it's been too long to remember :-(

- Materials:

- Body: HDPE, Cover: 4mm Acrylic Sheet, Gasket: Craft Foam (Walmart), Spinner: ABS Filament

I have attached Step files, but would be happy to export into STL or whatever anyone might want!?!?

Here's a short video of the working as well as a couple quick photos...

Intermediate Makersl Msl-10 Co2 Laser Flow Meter

Workshop Project created by Sonny Lowe, Apr 25, 2017

Share this Project

Dan McCloskey, Jason Pulliam, yurayko and 3 others like this.

User Comments

Sort Comments By