Hello,

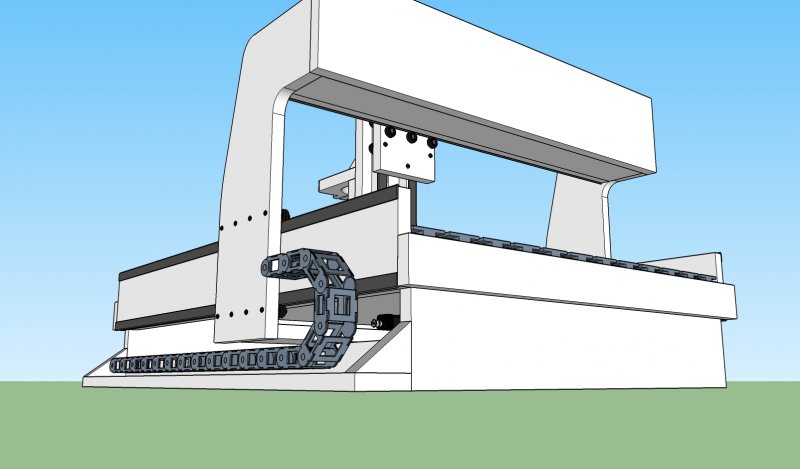

This is my first attempt to build a CNC Table. I am a sign maker by trade and thought it would be fun as well as useful to have this machine in my shop.

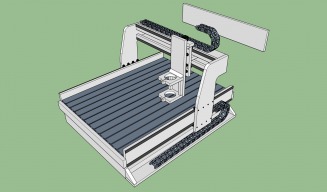

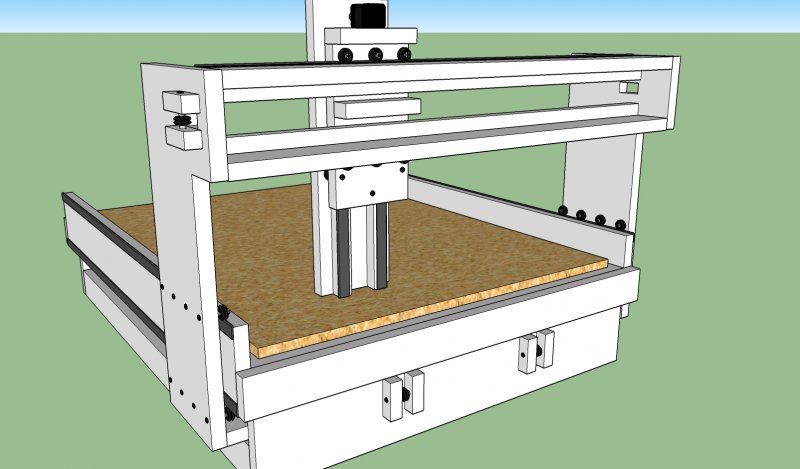

I intend to make it with a 3'x4' tabe bed, with the gantry spanning the 3' width. I have a 4'x8' by one inch PVC sheet that I am making it from.

Once I cut the pieces on my table saw I intend to use a special PVC glue as well as screws to put the body parts together. I believe using the 1 inch PVC should give this machine plenty of rigidity and strength.

My first purchases will be the Side mount linear rails for all the guides as well as the V-Wheels.

I am trying to see how cheaply I can build this machine while maintaining a high degree of overall durability and precision.

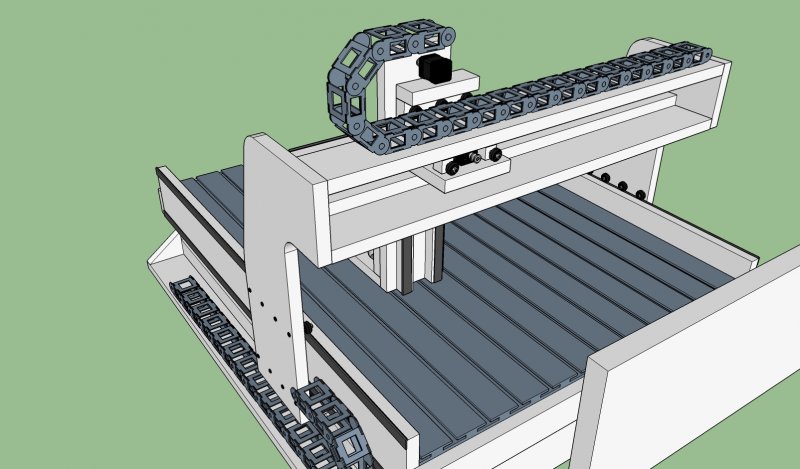

At the moment I plan on having all the moving parts be belt driven. I have been using vinyl plotters that are belt driven for many years. I believe belt driven machines are very durable as well as accurate and very maintenance free.

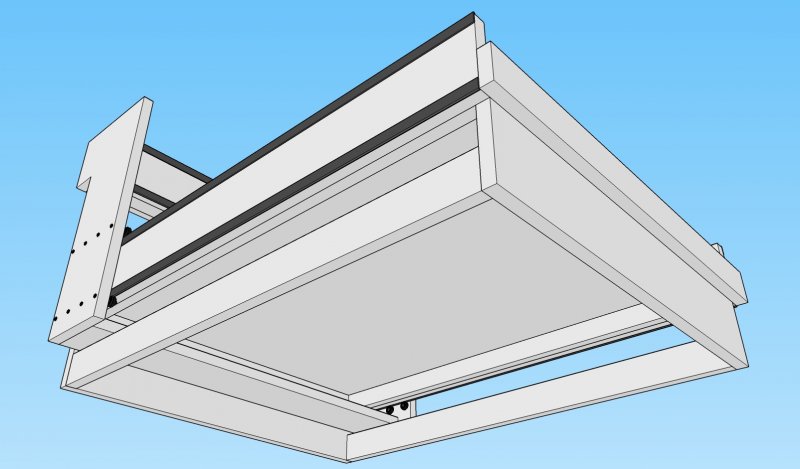

I have yet to decide exactly how I want to mount the stepper motors. I'm thinking of making the bottom deeper and mounting two motors with belts on a cross beam on the bottom as to keep the gantry belts hidden and free of dust. I plan on using two drive belts for the gantry with two stepper motors. (Any Suggestions are more than welcome.)

Well, that is where I am at at the moment. i still have tweeking to do to the Sketchup design. By the way, I am a huge fan of Sketchup. It is very easy to design in and it is free. No better way to design and redesign before you cut a thing.

Update: I have done some more adjusting to my design to allow for my belts and pulleys. I will be using 90 degree stepper motor mounts.

Sketchup Design of a PVC CNC I Intend to build.

Build in 'CNC ROUTER BUILDS' published by Dave Ashley, Feb 3, 2016.

Build Start to begin Feb 1st.

-

-

-

- Build Progress:

-

- Build in Progress...

-

Special Notes

Any suggestions would be very much appreciated.

Ricardo Almeida and kram242 like this. -

-

Build Author Dave Ashley, Find all builds by Dave Ashley

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution - CC BY

Reason for this Build

I am building this machine for fun as well as to educate myself in CNC Mechanics.