I have recently been upgrading and improving my Prusa i3 derivative so that it no longer looks like the original thing I built but has much better print quality and more bells and whistles. Unfortunitely I then saw a youtube video about a 3d printable violin, that requres at least one print dimensio to be 30 cm!

Sooooo, I have decided to create a new build from scratch, everything designed by me hardware wise, with a multi colour print head up top, a z axis moving hot plate on decent lead screws rather than the cheap ones off ebay, and a 50cm cubed (approx) print area.

Progress:

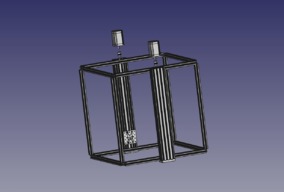

After spending 3 days trying to import STEP files with the openbuild models and failing dismally, I looked in some of the forums and found FreeCAD seemed to be able to import them and I decided to try that. Please note that I have absolutely no experience in CAD and so this is still a learning curve. I have made a box, with two c sections on the outside to allow the Z axis to utilise as much of the 50cm height as possible, and I am going to have the X/Y hardware also outside the box with a single mixer nozzle so that there are no extra offsets due to multiple extruders.

To keep the print head as light as possible, I amd going to have a raft above the print area for the extruder motors and use bowden extruders to the print head.

Any comments or suggestions greatly appreciated!

20/09/2017

The C-beams have been moved out to allow the z axis more travel room, end plates ,moving z axis plates and flexible couplers added. The Z motors have been moved out of the way in an 'exploded' diagram fashion.

I am still learning the CAD although it is a bit easier and I am currently playing with designs to give the print head as much x/y movement as possible.

12/09/2017:

the very basic image of what I am thinking of doing has changed radically, I have worked out how to cut out bits and cur lengths down in FreeCAD. The main change is altering the top and bottom vslots supporting the z axis workings from single to double. The next staage will be changing this to tripple with the cut out across two spand. This should allow the z axis plates to have a greater movement and stop the loss of z direction when the plate hits the support struts.Stepper motors and base plates added.

Printer number 2

Build in '3D PRINTER BUILDS' published by Wombaticus, Sep 20, 2017.

A Large Printer that will hopefully be able to print at least 45cm cubed

-

-

-

- Build Progress:

-

- Build in Progress...

-

Special Notes

A quick bit about me,

Fat, Ugly, Boring, Nerd... who has heard that sexy women like honesty

seriously though I am out of work due to long term illness which affects my concentration. My first printer, a Prusa i3 derivative took almost 3 years to build as when things went wrong or I hit a snag, I couldn't face doing anything for several months.

My health is improving to the point where getting back to work is a distant, but now plausable idea and as I was an Electronics engineer, I want a project to reconnect with my old job. Also in this case, learn a bit about CAD too

Rui Vasconcelos likes this. -

-

Build Author Wombaticus, Find all builds by Wombaticus

-

- Loading...

-

Build Details

- Build License:

-

- GNU (GPL3+) General Public Licence

-

Attached Files:

-