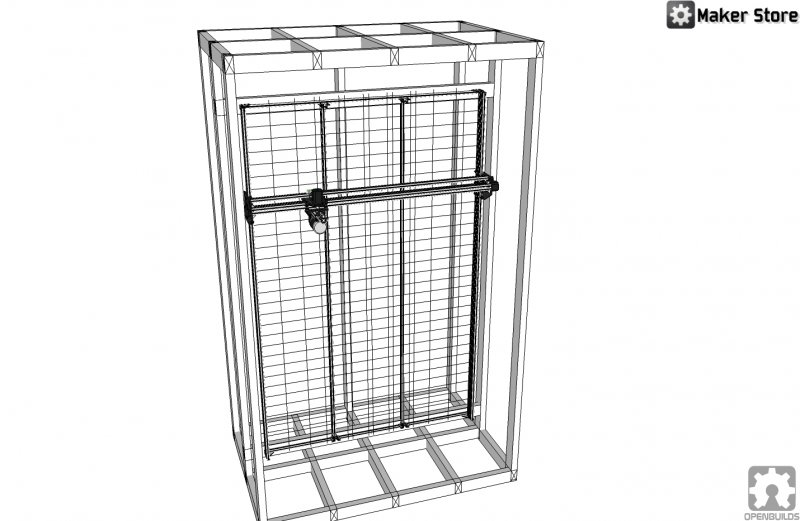

Something i've been messing with the idea for is a self-containd, CNC spray booth.

We spray loads of flat items with a HVLP spray gun.

While the current process works great, i'm sure we can speed things up, increase consistency, and reduce the footprint required for the process.

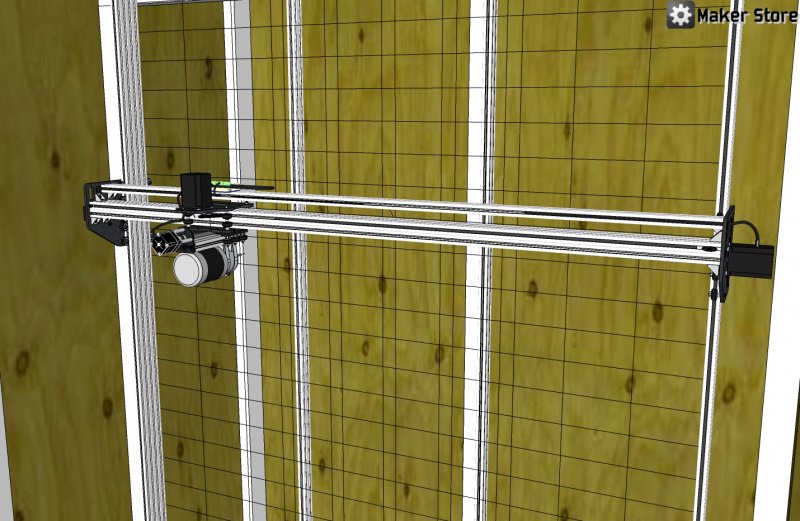

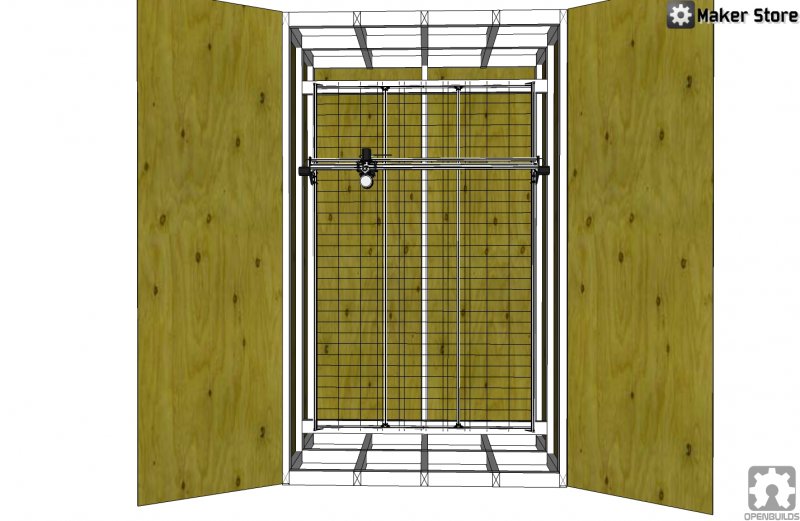

Basically i'll be using a large OX - 2400 x 1500, mounted inside a booth (approx 900mm deep, but to be determined), and an electronically controlled HVLP spray nozzle which we'll feed our required product to.

The cabinet itself will contain all fume extraction and incoming ventilation.

The idea is that i put the product inside, set the size, and hit go.

We end up with a consistent finish across the board.

Loads more details to come, but i've just ordered the OX kit to begin the build.

Once i've satisfied dimensions etc, i'll start working up the frame for the cabinet.

=======================================================

UPDATE 12 AUGUST 2015

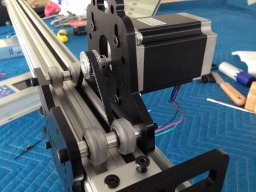

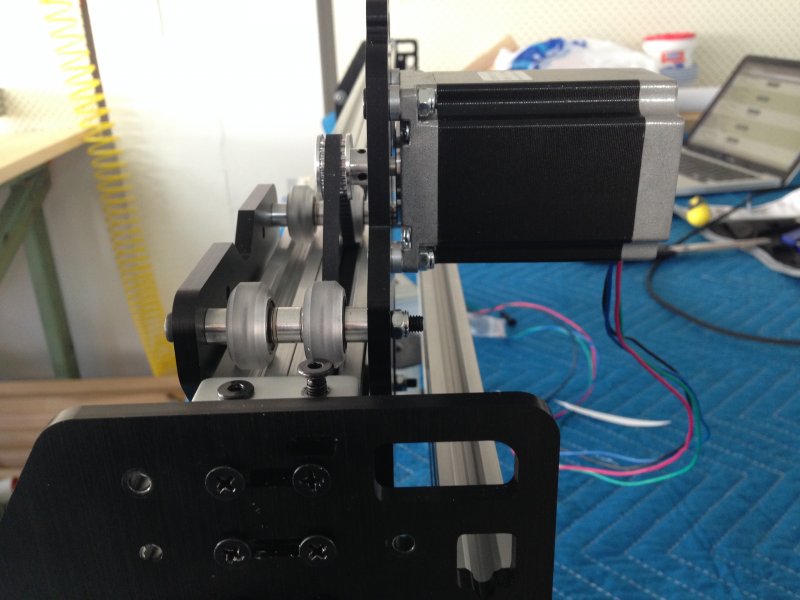

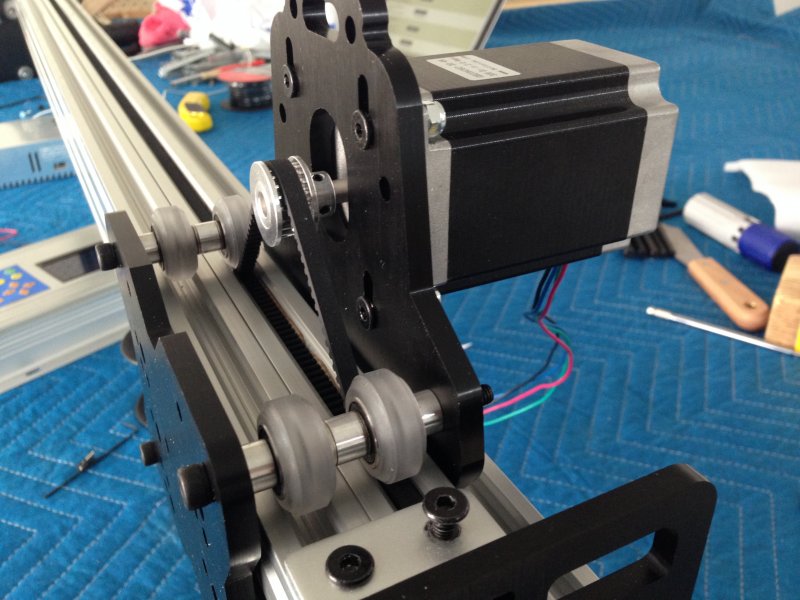

So i have my x/y axis running well. Everything needs to be finished / tidied up quite a bit, but there's been much testing, so didn't want to make it too neat yet...

I have a 4-axis TB6560 with NEMA23s using Mach3.

I have installed counterweights on the inner rails to offset the 10kg or so of gantry.

I'll take some better photos once it's cleaned up, but here's a really crude video of it running during testing (still have to tension some belts etc).

I wrote a very quick and dirty GCode file to simulate the spray-gun passes we'll be configuring, and it worked precisely as planned. I'll have to take a video of that too.

Still lots to do:-

1. Tidy up all wiring.

2. Add a little more weight to the counterweights, and secure them to their sliders properly.

3. Reposition pulleys for better range of motion (they were crudely positioned to test the concept).

4. Design and build spray-gun holder.

5. Everything else i can't think of right now...

Then of course, the whole cabinet and ventilation...

=======================================================

UPDATE 31ST JULY 2015

I purchased a large OX kit - 2400 x 1500 from Maker Store here in Australia.

I've been putting it together, and build progress is going well. Though i've been modifying small things as i go.

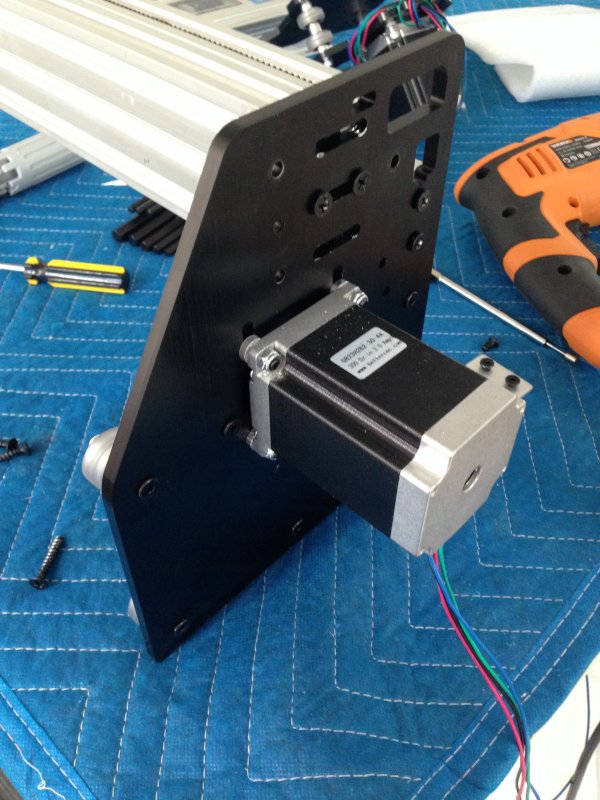

I've tested the stepper with my controller, which is only a 3-motor controller, since i don't have a Z-axis. The sled on the gantry works great. I haven't finished belt setup on the X axis, but have tested the motors.

I did realise after i commenced the build that since i'm mounting this standing up, i'm going to have to counterweight the gantry, as there's no way the steppers are going to take the 6kg weight of the gantry and still move at a good without overheating. It would also create too much strain on the belts and they would stretch in no time. So i'm mounting two small sleds with a cable and pulley, each with 3kg on them, to counterweight the gantry. Should work great.

Anyway, we all love pics, so here's a few progress pics crudely taken on my phone...

OX-Based Self-Contaned HVLP Spray Booth

Build in 'Everything Else' published by robbell, Aug 13, 2015.

A CNC HVLP spray booth based on OX.

-

-

-

- Build Progress:

-

- Build in Progress...

jacksondeep, Lukas K, Martin Green and 6 others like this. -

-

Build Author robbell, Find all builds by robbell

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution NonCommercial - No Derivs - CC BY NC ND

Reason for this Build

To solve a problem, and increase efficiencies.