I am studying in mechanical engineering since 4 years now, and was always interested by 3d printing. Recently I started looking at FDM printers, and had not found a printer that had both good mechanical features and good price. So I am planning to design my own, merging all the features that I found interesting.

First, you have to note that my first language is not english, I am french canadian and I assume that I could make some errors. Sorry for that, the goal here is to get some advice and show how my desing is progressing. I am doing most of my work on SolidWork, and I would like to have a solid design before I order parts to build the printer. I will work few hours per week on that project, so it could take several time before I achieve my goal.

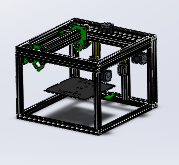

Let start with a detailed picture of my progress:

As you see, I plan to use 2 stepper for driving the X carriage, and 1 stepper for driving the hot end along Y axis. The Z axis would be driven by 1 stepper, and sliding on HIWIN style guide rail, for less deflection along Y. I am interested in ACME lead screw drive system for all axes, since it seem to me that it is a more precise driving solution.

There are some exemple of screw I would use for driving (subject to changes):

Z:Ø3/8-8, 1 start

X and Y: Ø3/8-8, 4 start

There come your experience:

1.Should I avoid using 2 stepper for driving the X axis?

I have seen Z axis driven by 2 lead screw (RepRap), but there is less movement in Z axis than in the X axis. Is desynchronisation a common problem? Should I use 1 stepper, driving 2 lead screw by a GT2 belt for the X axis?

2.Should I use anti backlash nut for X and Y?

Since I have seen some build not using them like the Lautr3k 3D printer (correct me if I am wrong) while achieving very good precision.

3.Is using lead screw worth it?

Finally, I don't have easy acces to a 3D printer, so most of the part will be laser-cutted or machined.

I plan to enclose the printer with 1/8 aluminium pate.

My first 3D printer: Absolute3Dr

Build in 'Cartesian Style Bots' published by Philippe Bergeron, Dec 9, 2014.

You are about to read the evolution of my 3d Printer build.

-

-

-

- Build Progress:

-

- Build in Progress...

marsupilamo likes this. -

-

Build Author Philippe Bergeron, Find all builds by Philippe Bergeron

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution Share Alike - CC BY SA

Inspired by

Lautr3k 3D printer

![[IMG]](proxy.php?image=http%3A%2F%2Fi.imgur.com%2FFDRkgiQ.png&hash=1f9fdc4b7df9673e4113e7834f8fb5f4)