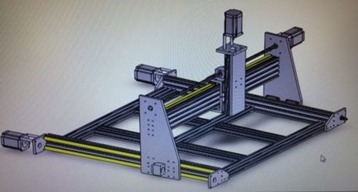

At this stage very much just CAD progress drawing and mochup rough design.

Just trying to work out bill of materials and overall sizing of machine work area

Goals:

reliablility

machinable area min 500x600x100

sturdy, minimum flex

budget: cheapest as possible while not skimping on quality parts where needed

bed area enclosed for cooling/liquid containment

Materials wanting to use:

ballscrew 1605 + components bk12,bf12 etc...

VFD controlled 2.2kw water cooled motor

48volts supply

387 oz.in Bi-Polar Stepper motors

Geckodrive G540 controller

Plan to look at misting/ fogbuster or equivalent system

Update 1: 6/9/17

change to linear rail, possible looking to swap from 1605 to 1204 for smaller components

dimensions

x 1092 overall

y 1000 overall

z gantry 275x90x10, x axis cbeam250

need to adjust offset on gantry endplates for spindle, just dont know what it needed to be at this stage....

x,y rail ,mgn15h 1 block on each rail

z rail ,mgn12h 2 blocks on each rail 4 total

still need to add new ball screw and endplates etc

Update 2: 18/9/17

gone with 1205 ballscrew

as we sit dimensions dropped to account for easier use of parts availability

bed 800x760 may change to account for ballscrew rod a little odd length, still need to work out with bearing blocks.

z clearance 100mm from lowest point on gantry, so depending on tool may have 85-90mm z height

![[IMG]](proxy.php?image=http%3A%2F%2Fimageshack.com%2Fa%2Fimg923%2F3091%2Fu4pdCg.jpg&hash=37c2d68d569a2e93fc6d1ab2b6e1743d)

![[IMG]](proxy.php?image=http%3A%2F%2Fimageshack.com%2Fa%2Fimg922%2F5193%2FO1OwAY.jpg&hash=8b7d20e96a70a3556a0dc3c26d3519de)

![[IMG]](proxy.php?image=http%3A%2F%2Fimageshack.com%2Fa%2Fimg924%2F3143%2F8D1vhd.jpg&hash=8b3963954cc807554dfc51a99dd647b8)

![[IMG]](proxy.php?image=http%3A%2F%2Fimageshack.com%2Fa%2Fimg924%2F1448%2FdBDQyX.jpg&hash=30ee8d67979faa8fdb0a7b06ff54fbb6)

Linear Rail derivative with ball screw

Build in 'Cartesian Style CNC' published by Bradles, Sep 18, 2017.

basic start to design of cnc machine

-

-

-

- Build Progress:

-

- Build in Progress...

-

Special Notes

would be great to hear peoples constructive feedback on areas that i might look into for revision changes or alterations to design

PeterGuu and Lord Chalfont like this. -

-

Build Author Bradles, Find all builds by Bradles

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution NonCommercial - No Derivs - CC BY NC ND

Reason for this Build

Friend and I have been discussing this on and off over the past 3 years to buy or build cnc, have finally gotten to the point where have actually sat down and been designing a machine.Inspired by

Ox, Sphinx, Cbeam

![[IMG]](proxy.php?image=http%3A%2F%2Fimageshack.com%2Fa%2Fimg924%2F5511%2FsJGJ76.jpg&hash=486ce161c78c15f87b17ac5084d27499)